This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

SK-400TR High-Spec Planetary Centrifugal Mixer – Advanced Performance for Demanding Materials

The SK-400TR is a high-spec planetary centrifugal mixer engineered for advanced applications requiring exceptional precision and speed.

With a 700g capacity, it is ideal for processing challenging materials such as carbon nanotubes, ceramic slurries, and aerospace sealants.

Its high-torque motor and individual revolution/rotation control system deliver unparalleled mixing uniformity, while optional Wave Mode boosts dispersion power for the most demanding tasks.

Individual revolution and rotation speed control system

Equipped with revolution and rotation individual speed control system.

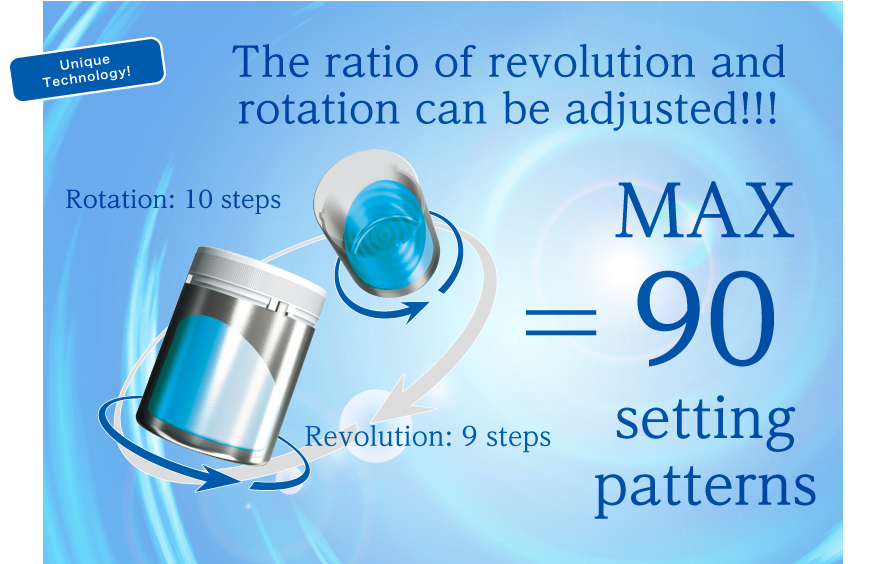

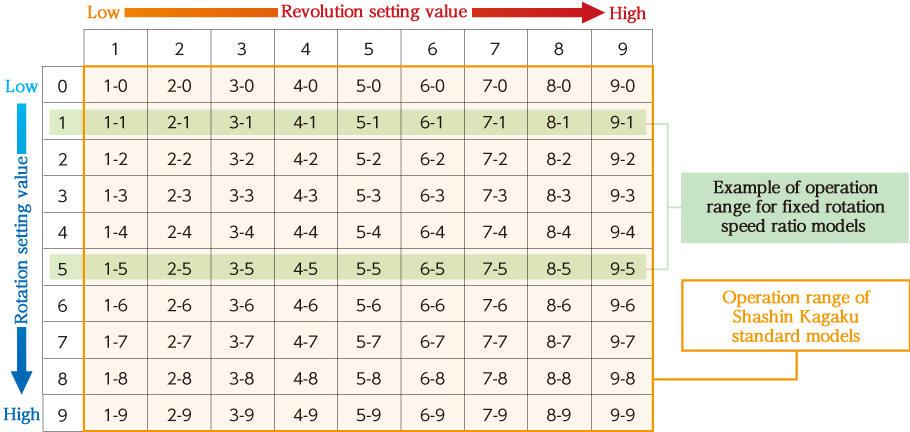

The ratio of revolution and rotation can be adjusted; thus 90 different speed combinations can be set.

All-in-one support of other applications (abrasive, coating, etc.).

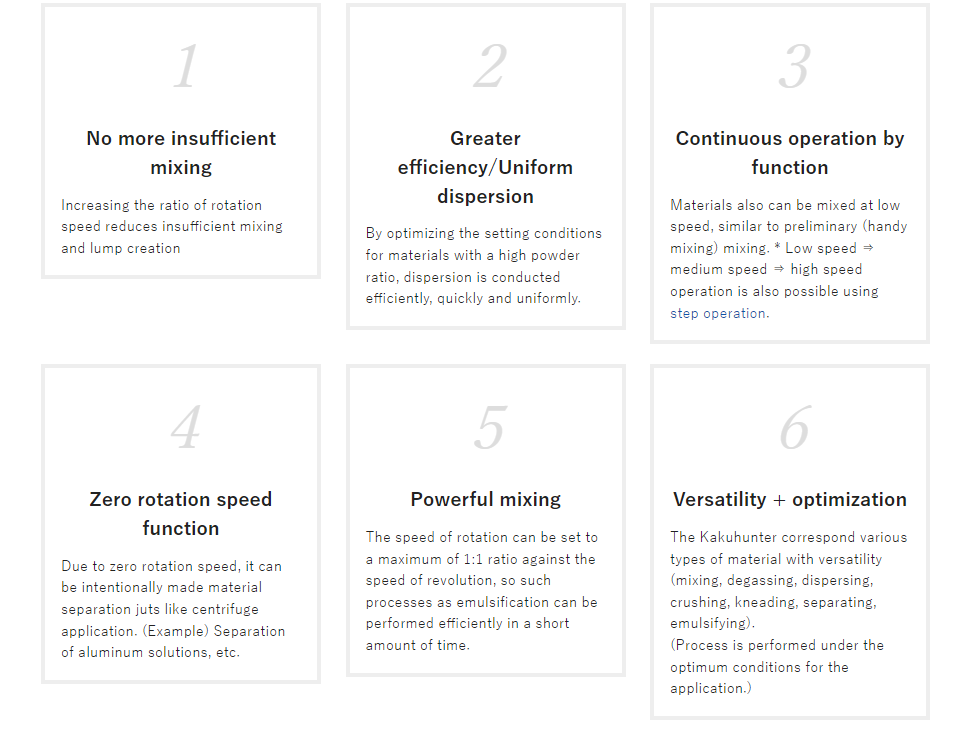

With ordinary models, the rotation speed ratio is fixed by the gear ratio, so even if the speed of revolution is adjusted, some materials may not properly mix or create lump, and practically these problems could not be solved.

By contrast, with the individual speed control system, revolution can be set in 9 steps, rotation in 10 steps, providing the advantages below.

6 advantages of variable rotation speed

Furthermore, this keeps the temperature of the material down!

Rather than simple adjusting the speed of revolution, the speeds of revolution and rotation are optimized, thereby sustaining the thermal elevation of the material.

Revolving speed setting table

To keep rotation direction is as usual, new function which revolving direction is changeable either clockwise or anti-clockwise for revolution. Under vacuum pressure, it may change material property, however it enables to achieve high precision degassing even atmospheric pressure condition.

To keep centrifugal force of revolution, it enables to achieve setting which revolving speed pf rotation can be surpassed to revolving speed of revolution. Mixing force is drastically enhanced, thus it can correspond to various materials case.

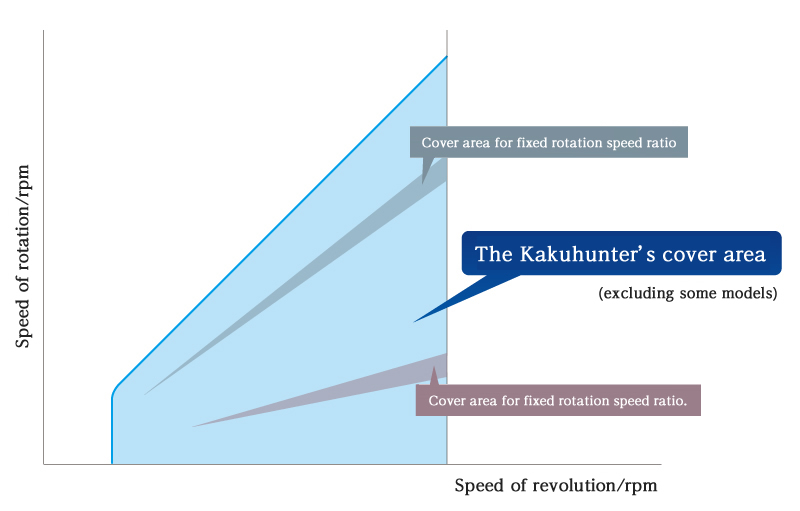

Revolving speed comparison graph

Capabilities of SK-400

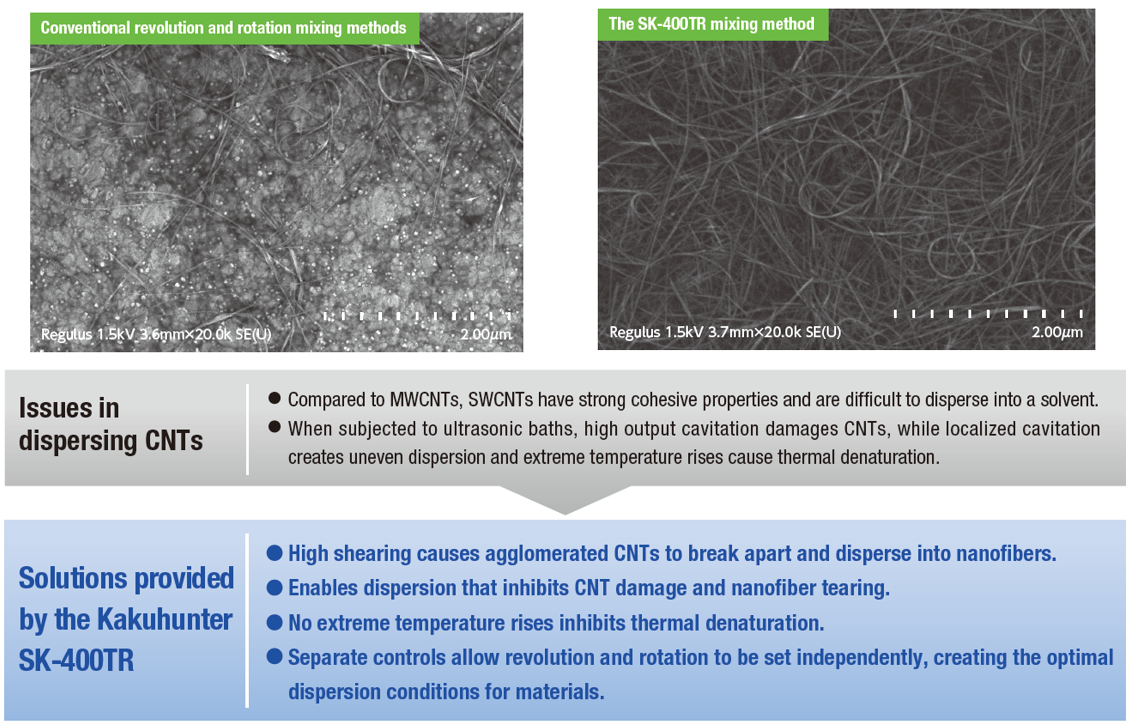

Nano dispersion of hard-to-disperse agglomerated carbon nanotubes

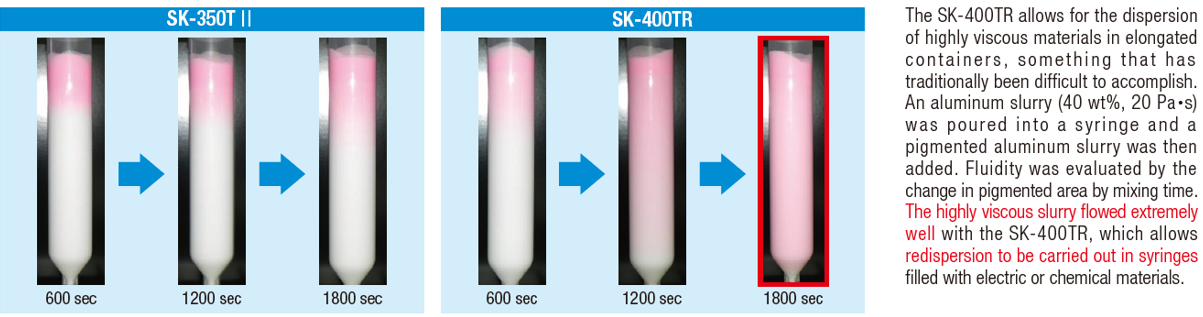

Comparison of the fluidity of highly viscous materials in elongated containers

Target materials: Alumina powder, silicone oil Container:

50 ml syringe Equipment compared: SK-350T II, SK-400TR

Key Features

1. Capacity: 700g gross / 300ml × 2 cups

2. High-Torque Performance: Handles heavy, filler-rich, or abrasive materials

3. Independent Revolution & Rotation Control: 9 × 10 combinations

4. Multiple Modes: Mixing / Medium / Degassing + Wave Mode

5. Rapid Processing: Short cycle times with consistent results

6. Non-Contact Mixing: Eliminates contamination and cleaning downtime

7. Safety: Lid lock, imbalance detection, overload protection

Advantages

● Designed for high-performance materials with strict quality requirements

● Superior dispersion of nano-scale particles and fillers

● Ideal for R&D and production of advanced composites

Application

🔋Energy: Carbon nanotube dispersion for battery electrodes

✈Aerospace: Sealant and adhesive preparation for structural components

⚡Electronics: Ceramic slurry for semiconductor manufacturing

🏭Industrial: High-viscosity composite blending

Specifications

| Cup size | 400ml x 2 cups, Gross weight 350g (container included) |

|---|---|

| Revolving speed | Opposite direction on revolution and rotation:

Revolution speed 300-1400 rpm Rotation speed 0-2000 rpm

Same direction on revolution and rotation: Revolution speed 300-1400 rpm Rotation speed 0-1400 rpm |

| Speed of revolution | Settable in 9 steps |

| Speed of rotation | Settable in 10 steps (There is limitation for rotation speed) |

| Settable time | 10-300 sec. |

| Step mode | 1-5 steps |

| Memory channel (condition setting memory) | Fixed CH 10CH |

| Condition setting Channel | User settable CH 90 CH |

| Power supply voltage | Single phase AC200-240V 50/60 Hz |

| Power consumption | About 2,000W |

| External dimensions | W552 × D650 × H750(㎜) (Exclude handle part) |

| Main unit weight | Approx. 100kg |

Kakuhunter Line up

Atmospheric Pressure Models

Vacuum Equipped Models

High-Spec Model

SK-400TR 300 ml × 2 cups ~ 700 g

|

Exclusive Models