This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

High-speed, wide-radius gyration mixer model, expertly designed for producing high-quality materials with controlled mixing and lump prevention.

Model equipped for both high-speed revolution and a wide radius gyration, supporting for the production of high-quality materials.

The timing by which the revolving speed of rotation increases is controlled to improve the mixing rate of powders and liquids and sustains the generation of lumps.

Planetary Centrifugal Mixer

Model:

SK-1100T

Maker:

SHASHIN KAGAKU CO., LTD.

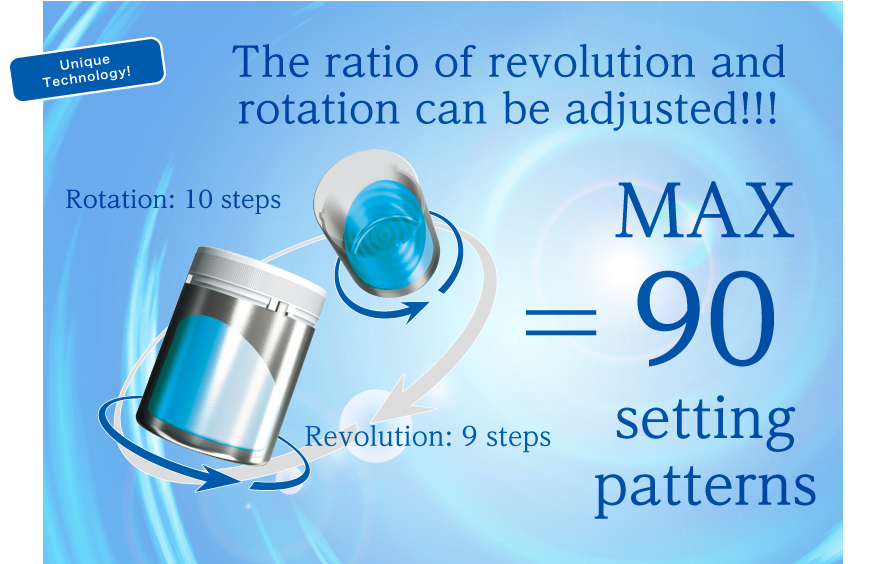

Individual revolution and rotation speed control system

Equipped with revolution and rotation individual speed control system.

The ratio of revolution and rotation can be adjusted; thus 90 different speed combinations can be set.

All-in-one support of other applications (abrasive, coating, etc.).

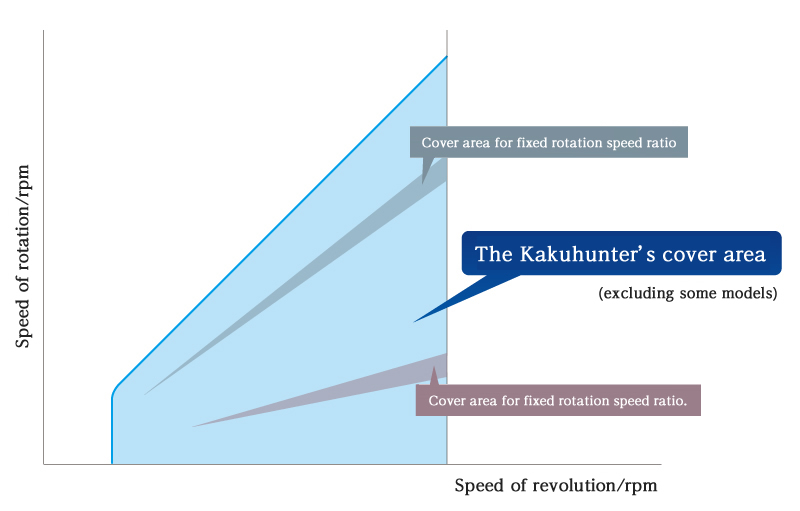

With ordinary models, the rotation speed ratio is fixed by the gear ratio, so even if the speed of revolution is adjusted, some materials may not properly mix or create lump, and practically these problems could not be solved.

By contrast, with the individual speed control system, revolution can be set in 9 steps, rotation in 10 steps, providing the advantages below.

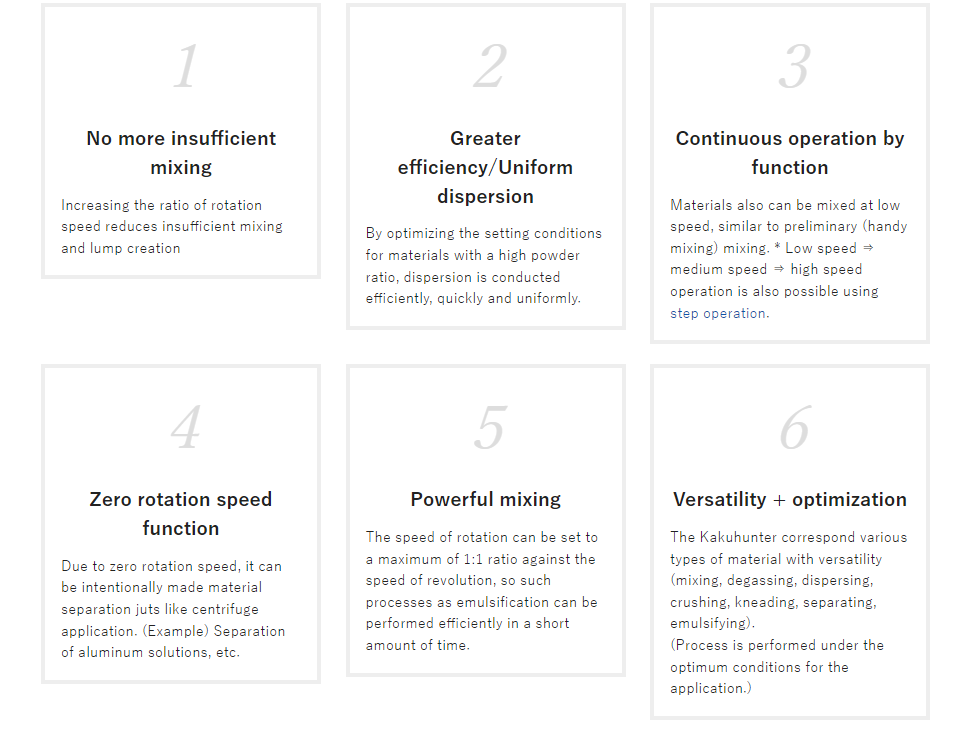

6 advantages of variable rotation speed

Furthermore, this keeps the temperature of the material down!

Rather than simple adjusting the speed of revolution, the speeds of revolution and rotation are optimized, thereby sustaining the thermal elevation of the material.

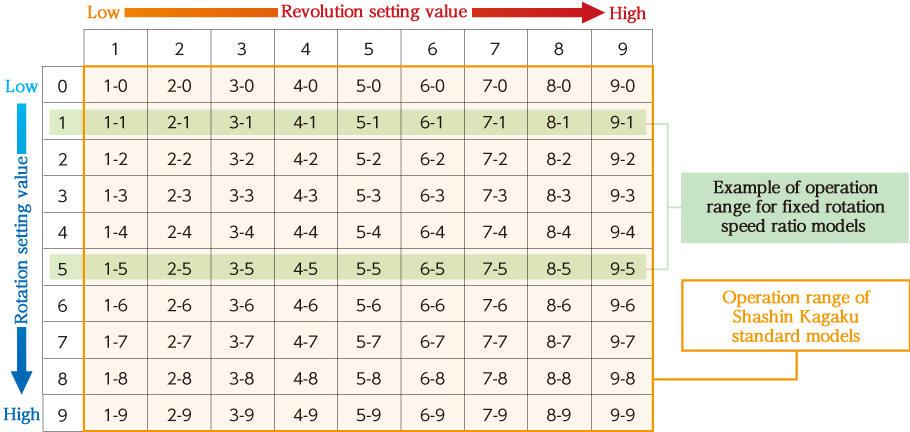

Revolving speed setting table

To keep rotation direction is as usual, new function which revolving direction is changeable either clockwise or anti-clockwise for revolution. Under vacuum pressure, it may change material property, however it enables to achieve high precision degassing even atmospheric pressure condition.

To keep centrifugal force of revolution, it enables to achieve setting which revolving speed pf rotation can be surpassed to revolving speed of revolution. Mixing force is drastically enhanced, thus it can correspond to various materials case.

Revolving speed comparison graph

Application

Specification

| Cup size | Maximum 1kg (Gross Weight) x 2cups |

|---|---|

| Other containers | Multiple containers and syringes can be used by using an adapter. |

| Speed of revolution | Settable in 9 steps |

| Speed of rotation | Settable in 10 steps (There is limitation for rotation speed) |

| Settable time | Maximum 990 seconds (5 Step total) |

| Step mode | 5 steps

Continuous operation with 5 different operation patterns (condition settings) is possible |

| Memory channel (condition setting memory) User settable channels Fixed data channels |

90 |

| Condition setting Channel | User settable CH 90 CH |

| Power supply voltage | Single phase AC200-240V 50/60 Hz |

| Power consumption | 2.0kW |

| External dimensions | W565 × D597 × H741(㎜) |

| Main unit weight | Approx. 140kg |

Related Products