This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

SK-350TII Planetary Centrifugal Mixer – Medium-Capacity Precision Mixing & Defoaming

The SK-350TII is a 700g-capacity planetary centrifugal mixer designed for laboratories, pilot production, and small-scale manufacturing.

With individual revolution and rotation speed control, it enables fine-tuning for a wide variety of materials, ensuring uniform mixing and efficient bubble removal without contamination or material loss.

Key Features

1. Capacity: 700g (gross weight) / 300ml × 2 cups

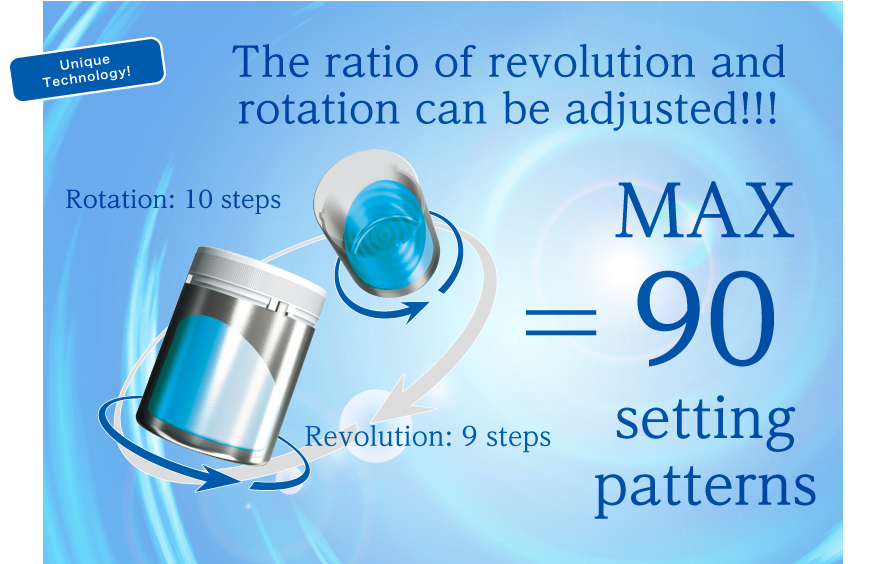

2. Independent Revolution & Rotation Control: 9 revolution steps × 10 rotation steps

3. Three Modes: Mixing / Medium / Degassing

4. Wave Mode: Increased dispersion force for challenging materials

5. Balance Navigation: Detects and corrects imbalance

6. No Cleaning Required: Non-contact processing without mixing blades or rollers

7. High Throughput: Processes medium-size batches in tens of seconds to a few minutes

8. Safety Features: Lid lock, unbalance detection, motor warning & maintenance alerts

●Advanced functions added to the basic model equipped with the individual revolution and rotation speed control system.

This model is equipped with a function allowing the speeds of revolution and rotation to be set separately. By using 2 cups with a 400 ml capacity and weighing a maximum of 350 grams※, up to 700 grams of material can be mixed and degassed.

A new high-speed mode and a separation prevention mode which sustain separation of materials with different specific gravities (such as powder materials and liquids) have been added, providing advanced functions in addition to the basic functions.

* The maximum weight depends on the properties of the material. This weight includes containers and adapters.

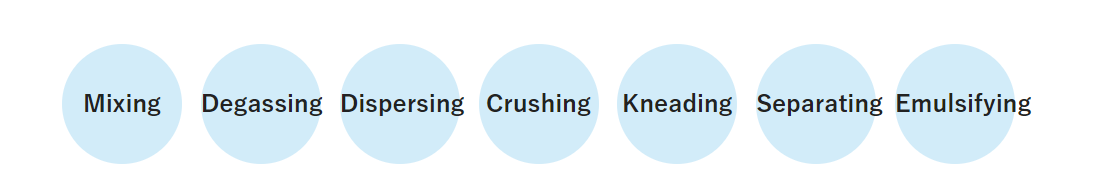

Applications

⚡ Electronics: Thermal interface material blending, solder paste mixing

🚙Automotive: EV battery adhesive preparation, conductive paste mixing

💄Cosmetics: Foundation and cream dispersion

🏥Medical: Medical-grade silicone degassing and mixing

🖌Coatings & Inks: Pigment dispersion for specialty coatings

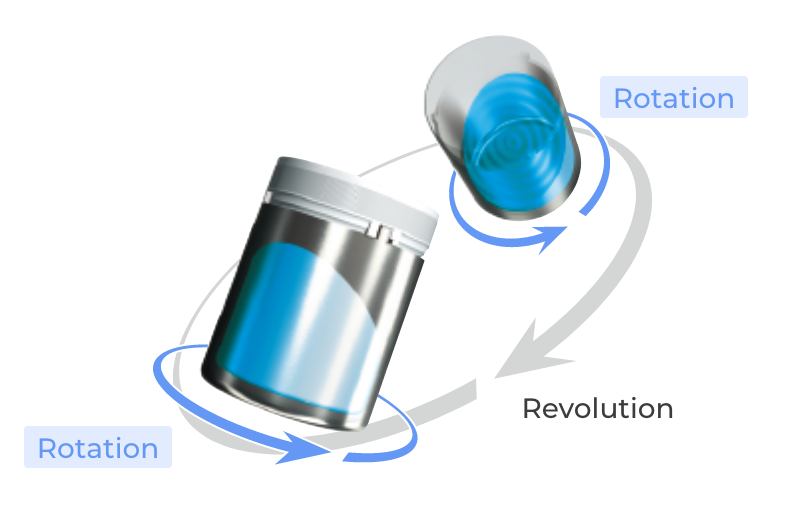

Individual revolution and rotation speed control system

Equipped with revolution and rotation individual speed control system.

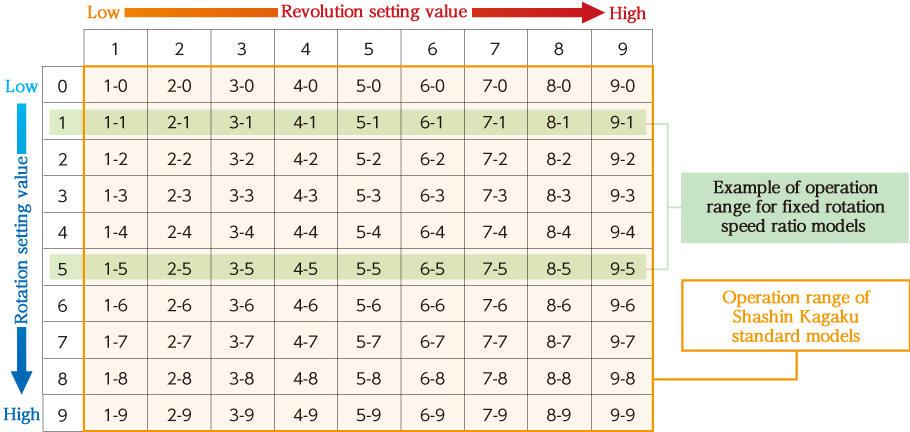

The ratio of revolution and rotation can be adjusted; thus 90 different speed combinations can be set.

All-in-one support of other applications (abrasive, coating, etc.).

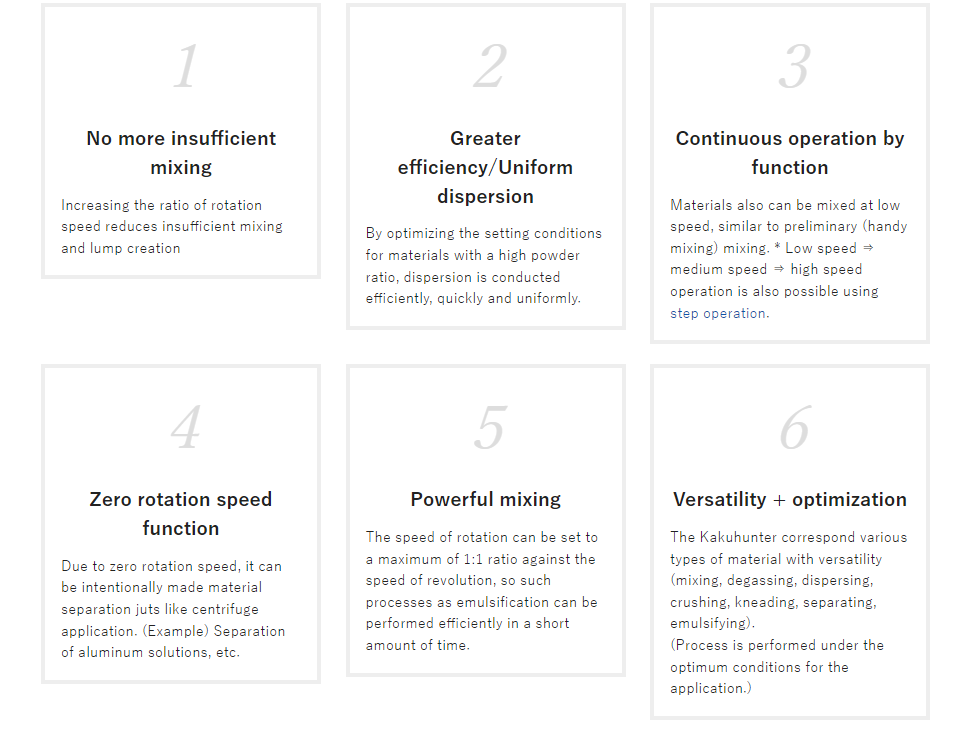

With ordinary models, the rotation speed ratio is fixed by the gear ratio, so even if the speed of revolution is adjusted, some materials may not properly mix or create lump, and practically these problems could not be solved.

By contrast, with the individual speed control system, revolution can be set in 9 steps, rotation in 10 steps, providing the advantages below.

6 advantages of variable rotation speed

Furthermore, this keeps the temperature of the material down!

Rather than simple adjusting the speed of revolution, the speeds of revolution and rotation are optimized, thereby sustaining the thermal elevation of the material.

Revolving speed setting table

To keep rotation direction is as usual, new function which revolving direction is changeable either clockwise or anti-clockwise for revolution. Under vacuum pressure, it may change material property, however it enables to achieve high precision degassing even atmospheric pressure condition.

To keep rotation direction is as usual, new function which revolving direction is changeable either clockwise or anti-clockwise for revolution. Under vacuum pressure, it may change material property, however it enables to achieve high precision degassing even atmospheric pressure condition.

To keep centrifugal force of revolution, it enables to achieve setting which revolving speed pf rotation can be surpassed to revolving speed of revolution. Mixing force is drastically enhanced, thus it can correspond to various materials case.

Kakuhunter Application and Introduction

Specifications

| Cup size | Maximum 350g (Gross Weight) x 2 cups Various syringes |

|---|---|

| Other containers | Multiple containers and syringes can be used by using an adapter. |

| Speed of revolution | Settable in 9 steps |

| Speed of rotation | Settable in 10 steps |

| Settable time | 10-300 sec. × 5 steps |

| Step mode | 5 steps Continuous operation with 5 different operation patterns (condition settings) is possible. |

| Memory channel (condition setting memory) | User settable channels: 90 Fixed data channels: 10 |

| Power supply voltage | Single phase AC200-240VAC 50/60 Hz |

| Power consumption | About 1,380W |

| External dimensions | W400 × D482 × H495(㎜) |

| Main unit weight | Approx. 50kg |

Kakuhunter Line up

Atmospheric Pressure Models

SK-300SII 300 ml × 1 cup ~ 310 gEntry model with Medium & Wave modes. Ideal for small labs needing precise mixing and degassing of varied materials.

|

SK-350TII 400 ml × 2 cups ~ 700 g90 speed patterns with separation prevention mode. Perfect for R&D and small-scale production.

|

SK-1100T 1100 ml × 2 cups ~ 2.2 kgHigh-speed, wide-radius mixer for high-quality production and lump prevention.

|

SK-2000T 2000 ml × 2 cups ~ 4 kgCustom high-capacity mixer for diverse industries. Excellent for large batch mixing and dispersion.

|

SK-3000TII 3000 ml × 2 cups ~ 6 kgFor mass production with consistent results. Excellent for heat-sensitive materials.

|

SK-4000T 4000 ml × 2 cups ~ 8 kgHigh-capacity industrial model. Stable mixing for high-viscosity and multi-gravity materials.

|

SK-10000T 10000 ml × 2 cups ~ 20 kgFlagship large-batch mixer for heavy industrial use. Designed for maximum throughput and uniformity.

|

||

Vacuum Equipped Models

SK-300TVS-A 300 ml × 2 cups ~ 600 gCompact vacuum planetary mixer for precise mixing and complete bubble removal in lab environments (optical & medical).

|

SK-350TV/TVS 400 ml × 2 cups ~ 700 g90 speed patterns + vacuum degassing. Syringe‑friendly, repeatable quality for adhesives, TIMs, and coatings (pilot lines).

|

SK-1100TV/TVSII ~10 L × 2 cups ~ 20 kgLarge‑capacity vacuum mixer for filler‑rich materials. Industrial‑grade uniformity for EV electrode slurry and optical adhesives.

|

SK-4000TV ~5 L × 2 cups ~ 10 kgHigh‑throughput vacuum degassing for production environments. Stable QC for battery materials and industrial resins.

|

SK-10000TV ~10 L × 2 cups ~ 20 kgUltra‑large vacuum planetary mixer for mass production in EV, aerospace, and high‑end electronics—microbubble‑free at scale.

|

High-Spec Model

SK-400TR 300 ml × 2 cups ~ 700 gHigh‑torque, fast‑cycle planetary mixer for advanced dispersion (CNTs/ceramics). Optional vacuum; precision for aerospace & semiconductors.

|

Exclusive Models

SK-BS12T ~2 L × 2 cups ~ 4 kgExclusive, multi‑process platform (mix/dispersion/knead). Custom container compatibility for specialty cosmetics and medical adhesives.

|

SK-MP12T ~2 L × 2 cups ~ 4 kgMulti‑purpose exclusive model with flexible recipes and repeatable scale‑up—ideal for R&D platforms and custom pilot lines.

|