This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

SK-1100TV / SK-1100TVSII – 20kg Industrial Vacuum Mixing System

Request a Quote

The SK-1100TV/TVSII is a 20,000g capacity industrial-grade vacuum planetary centrifugal mixer. Designed for large-scale production,

it combines high-torque centrifugal force with vacuum degassing to deliver uniform, bubble-free results in high-viscosity and filler-rich materials.

7 Key Features

Capacity: 20,000g gross / ~10L × 2 cups

Dual Technology: Vacuum + centrifugal mixing

Independent Speed Control: 9 × 10 settings

Multiple Modes: Mixing / Medium / Degassing + Wave Mode

Built for Industry: Handles high-density and abrasive materials

Safety: Lid lock, vacuum interlock, imbalance detection, overload alerts

Advantages

● Perfect for large-scale adhesive and slurry production

● Eliminates microbubbles to meet strict industrial quality standards

● Shortens production cycles by combining mixing and degassing

Basic Features

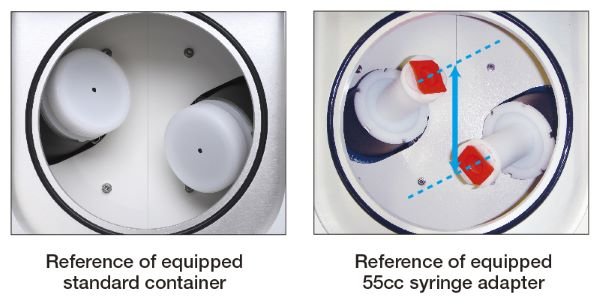

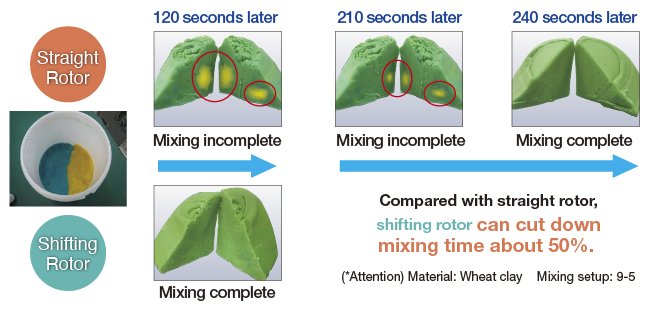

Two types of cup trays are available and can be selected according to purpose: straight (SK-1100TVIII) and shifted (SK-1100TVSIII)

While the straight type prioritizes the throughput, the shifted type improves the mixing ability as the contact surfaces between containers and materials are increased compared with the straight type.

* The effects differ with materials. You can choose either type according to your target throughput and mixing ability.

Comparison of Mixing Time (Straight Rotor vs Shifted Rotor)

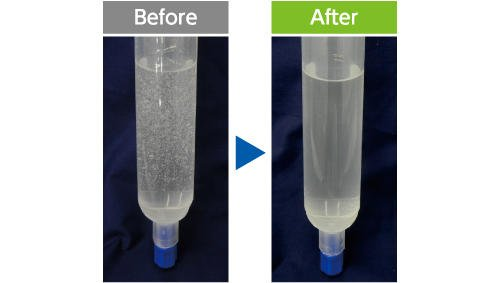

Powerful Defoaming by the Vacuum Reduced Pressure Function

– By vacuum reduced pressure in the chamber, even microlevels of fine air bubbles can be defoamed to improve quality stability.

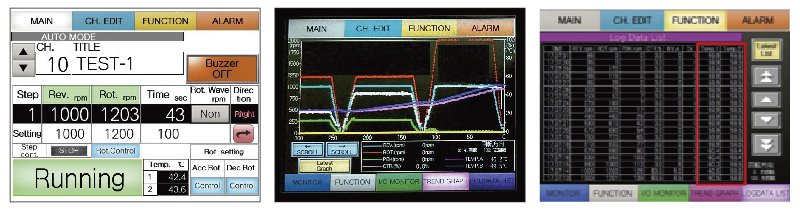

Powerful Mixing by Significantly Increasing the Rotational Speed (Individual Speed Control System)

Setting ranges are wider than that of conventional machines, making it possible to select conditions suited to the materials.

The Speeds of Revolution and Rotation, Temperature Rises, etc., can be Monitored Simultaneously

During operation, the speeds of revolution and rotation as well as temperature changes of the materials can be monitored simultaneously. This makes it easier for setting of optimum operating conditions according to material characteristics.

Applications

🔋Energy: Battery electrode slurry for EV and grid storage

🚙Automotive: High-volume adhesive production

🖌Industrial Coatings: Pigment dispersion with vacuum degassing

⚡Electronics: Encapsulant and potting compound production

Specifications

| Cup size | 1100ml x 2cups Various syringes of 100cc or less Various barrels of 170cc or less |

|

| Max throughput | 1kg x 2cups | |

| Other containers | A variety of containers and syringes can be used by use of an adapter | |

| Cup tray | Straight: SK-1100TVIII Shifted: SK-1100TVSIII |

|

| Speed of revolution | Settable at 9 steps | |

| Speed of rotation | Settable at 10 steps | |

| Settable time | 10 ~ 900 sec. x 5 steps * 5 steps totaling up to 25 min. |

|

| Step mode | 5 steps Continuous operation can be performed with 5 different types of operation patterns (condition settings) |

|

| Conditions setting memory | User-settable channels | 90 CH |

| Fixed data channels | 10 CH | |

| Power supply voltage | Three-phase 200-240VAC±10% Three-phase 385-415VAC±10% 50/60Hz |

|

| Power consumption | 3.0kW | |

| External dimensions | W732 x D820 x H836 (mm) (except for the pump) | |

| Weight of the main unit | Approx. 260 kg (except for the pump) | |

* It differs machine throughput depending on materials characteristic.

* Revolving speed may change depending on materials characteristic.

* Detailed specification may change without prior notice.

Kakuhunter Line up

Atmospheric Pressure Models

Vacuum Equipped Models

High-Spec Model

SK-400TR 300 ml × 2 cups ~ 700 g

|

Exclusive Models