This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

Supports AC withstand voltage / DC withstand voltage / insulation impedance measurement functions, capable of storing measurement data via USB, and supports PC connection software.

MICROTEST 7631 is a 3-in-1 test instrument that supports AC withstand voltage, DC withstand voltage, and insulation resistance testing functions. It has a maximum AC withstand voltage of 5000V with a leakage current of 30mA, a maximum DC withstand voltage of 6000V with a leakage current of 10mA, and a maximum insulation resistance of 12000MΩ. It provides 8 sets of testing channels and can be optionally equipped with the 7508/7516 multi-channel scanning box, allowing up to 72 sets of testing channels. It supports PC connection software for remote programming and storage of test data. It can also be linked to a barcode scanner for barcode scanning, facilitating production traceability management.

Hipot Tester

Model:

7631

Maker:

MICROTEST

Safety Certification Testing Items

- _AC Hi pot

- _DC Hi pot

- _Insulation Resistance

- _Current Leakage

AC/DC Withstanding Voltage Test

Difference between AC and DC

| AC Hi pot Test | Most DUT have parasitic capacitance.

With AC test, might not able to charge the parasitic capacitance. Therefore, this will create constantly current go through. |

| DC Hi pot Test | The parasitic capacitance will be charged under

DC hi-pot test. Therefore, the current will reduce to almost 0. |

Advantages for AC Test

| AC Hi pot Test | AC test is same as our normal usage electricity.

Also, AC is able to do positive and negative polarity test.

AC test won’t charge the parasitic capacitance on the DUT, so it won’t create instantaneous peak current. Do not need to discharge the DUT after testing. |

| DC Hi pot Test | The parasitic capacitance on DUT has been

charged under DC test, so the rest leakage current is the real current from DUT. |

Disadvantage of AC/DC Hi-pot Test

| AC Hi pot Test | If the DUT has huge parasitic capacitance, the current we detect will bigger then the actual current.

To fulfill the necessary current for the capacitance of the DUT, the output current is much more than DC test. This is danger for the operator. |

| DC Hi pot Test | Testing Voltage has to increase from 0.

The higher parasitic capacitance has, the more time it needs for DC voltage to increase. The voltage increase slower when it goes up. However, if the charging current is too high, it may cause the misjudgment for the instrument.

The discharge process is necessary after DC hi-pot test.

DC test can only do the single polarity test. |

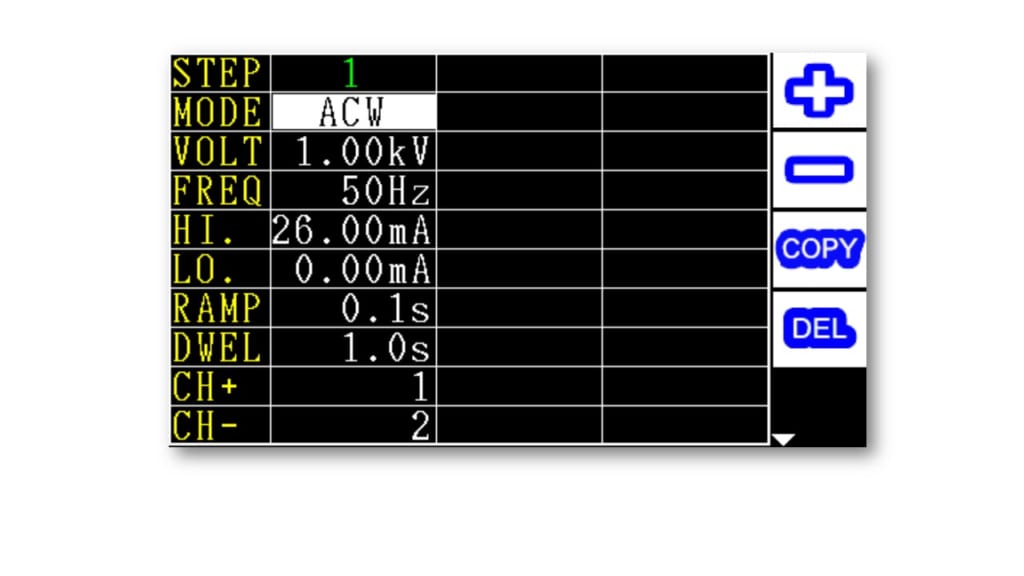

Hi-pot Test Time

The testing voltage is refer to the condition of DUT while doing Hi-pot test. If the voltage setting is too low, the insulation material defect might not be detected. If the voltage setting is too high and the testing time is too long, it may cause the permanent damage for the material.

Normally setting for the safety standard.

Formula →Testing Voltage= DUT recommend voltage × 2+1000V

EX : DUT standard :240V →Setting test voltage:1480V

Common way to safe time for testing

Testing time for most products is 60s. If there are more than one test on one item, it will cost a lot of time. This will lower the efficiency og the product line.

Therefore, the product line usually shorter the testing time to 1~2 sec. and higher 10%~20% testing voltage.

Features

- 8 Channels

- Hi pot ACW 5KV/30mA

- Hi pot DCW 6KV/10mA

- Insulation 1KV/12000MΩ

- Arcing detection

- True RMS measurement circuit

- Measuring Time (0.1 ~ 999s)

- Adjustable ramp time (0.1 ~ 10s)

- Safety Switch(INTER LOCK)

- Option PC Link Software

- 7508/7516 (8/16 channels) expansion box

- Support AC 5000V, DC 6000V, Insulation Resistance 12GΩ

Application

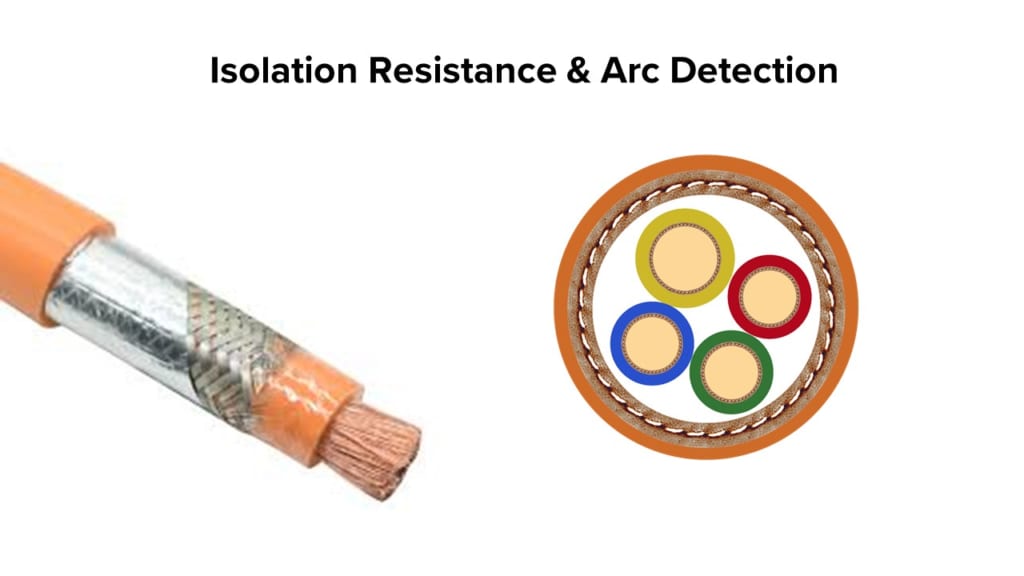

What is Insulation Resistance Test

VDE and TUV safety standard request insulation resistance test for some specific product before hi-pot test. The reason is to make sure the insulation will not be damaged while doing hi-pot testing. Insulation resistance test is the key item to evaluate the material.

Hi-pot test is judge by leakage current, but IR test is judge by resistance, and usually it’s higher than 1 MΩ. It tests the DUT’s resistance between both terminal.

Why Do We Need To Do IR Test

Confirm the performance of the structure of the insulation.

The insulation structure should have higher insulation resistance rate by using better material.

For the insulation material, the protection against electric shock of the switch must be guaranteed.

Confirm the insulation structure can pass the reliability test(heat durability, insulation)

The importance of insulation resistance.

Before assemble the product, IQC has to do the IR test for every components, such as switches, transformers, resistors, capacitors, inductors, PCB, wire or cable to make sure the quality.

Leakage Current Test

→Measuring Tiny AC Leakage Current

DUT has tiny parasitic capacitance. This characteristic will create leakage current by resistance. Capacitor is a resistance component under AC voltage. This may cause the test result include the leakage current inside the instrument. If the DUT has low leakage current, we must consider capacitance , frequency, and the voltage we put.

Arc Detection

The surface or interior of the insulation material might discharge under high voltage test. Because of the lost of insulation performance, DUT may have temporary of discontinuity discharge.

Because that temporary discharge can’t be judge by leakage current, so Hi-pot tester will judge the defect product by the changing rate of testing voltage or leakage current.

Arc test is a geometric not a constant test. Also, the detection will be affect by the wire’s impedance or capacitance between the detectors. The rate of change of the current will be affect in the Arc detection.

Transformer safety regulation testing includes withstand voltage, insulation impedance, and leakage current measurements.

Specifications

| Model | 7631 |

| Test Channel | 8 |

| AC Output Voltage | 5000V |

| DC Output Voltage | 6000V |

| Insulation Resistance | 12000MΩ |

| Expansion box | 8 Chnnels (Model 7508) |

| 16 Channels (Model 7516) |

| AC Hipot | |

| Output Voltage | 10V-5000V |

| Voltage Resolution | 1V |

| Voltage Accuracy | ±(3% of setting+5V) |

| Rated Current (Max.) | 30mA |

| Upper Leakage Current | 0.001-31mA |

| Leakage Current Resolution | 0.001mA |

| Leakage Current Accuracy | ±(3% of reading +10uA) |

| Arcing Detection | Detect gears from 0-20

(1 is the most sensitive) |

| DC Hipot | |

| Output Voltage | 10V-6000V |

| Voltage Resolution | 1V |

| Voltage Accuracy | ±(3% of setting+5V) |

| Rated Current (Max.) | 10mA |

| Upper Leakage Current | 0.001-11mA |

| Leakage Current Resolution | ±(3% of reading +10uA) |

| Leakage Current Accuracy | 0.001mA |

| Arcing Detection | Detect gears from 0-10

(1 is the most sensitive) |

| Insulation Resistance | |

| Output Voltage | 10V-1000Vdc |

| Voltage Resolution | 1V |

| Voltage Accuracy | ±(3% of setting+5V) |

| Insulation Resistance Range | 1-12000MΩ |

| IR Resolution | 1MΩ |

| IR Accuracy | 100-500V, 1-1000MΩ

(±5% of reading+1MΩ) |

| 500-1000V, 2-12000MΩ

(±5% of reading +10MΩ) |

|

| Measuring Time | 0.1-999s |

| Ramp Time | 0.1-10s |

| Measuring Time Resolution | 0.1s |

| PLC Remote Control | Test、About |

| PLC Output Signal | PASS、FAIL、HV Output、Testing |

| Safety Switch | When testing, you need to short-circuit the

INTER LOCK on the rear of the instrument to output the test voltage |

| List Mode | Each group contains up to 32 steps |

| Built-in Storage | 15sets setting files |

| USB Host Storage | Storage setting files and update firmware |

| Power Supply | Voltage:90Vac-264Vac |

| Frequency:50/60Hz ±5% | |

| Power consumption | 300VA |

| Environment | Temperature:5℃-40℃ |

| Humidity:0-80%RH | |

| Dimension | 435x145x500 mm (W*H*D) |

| Weight | 15 Kg |

| Interface | RS-232、Remote、USB Host、USB Device

EXT. I/O |

| Display | 4.3″ TFT LCD (480*272 ) |