Achieving High-Precision Metered Dispensing

Structure

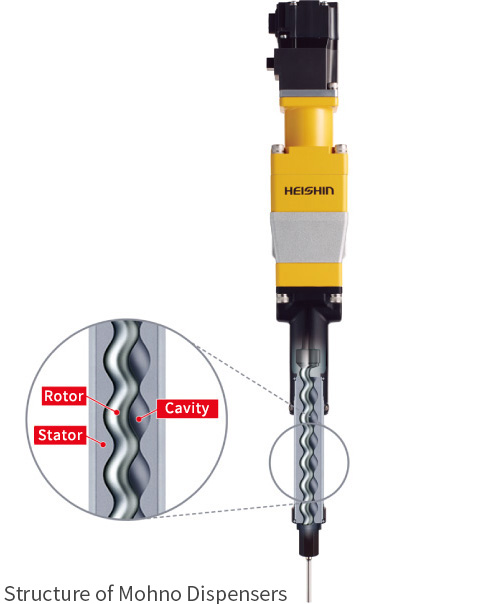

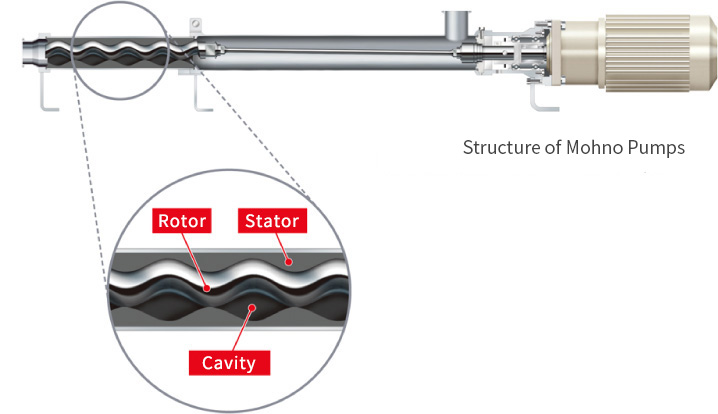

The Mohno Dispenser shares its basic structure with the Mohno Pump, operating as a progressing cavity pump (single-axis eccentric screw pump) with rotary volumetric displacement.

At its core, it consists of a rotor (analogous to a male screw) and a stator (analogous to a female screw). The interaction between the rotor and stator creates a series of sealed cavities known as “cavities” within the gaps between them. These cavities enable the precise, consistent, and high accuracy metered dispensing that the Mohno Dispenser is renowned for.

Principle

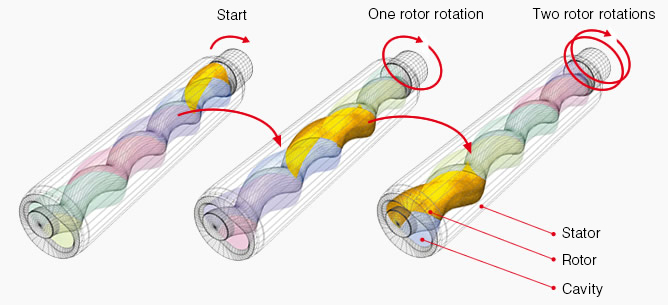

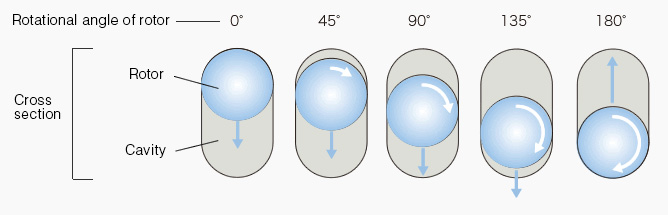

As the rotor rotates within the stator, it generates strong suction, capable of drawing in even high-viscosity fluids. This rotation continuously creates new cavities, which move the fluid from the suction side to the discharge side. The liquid trapped within these sealed cavities is transported forward in a continuous, non-pulsating flow.

Because the cross-sectional area of the cavities remains constant regardless of the rotor’s position, the volume of fluid dispensed is always consistent. The flow rate is directly proportional to the rotor’s rotational speed, allowing for precise control of the dispensing volume.

This design ensures non-pulsating, metered conveyance of fluids, achieving high-precision dispensing with consistent volume and flow rate. The Mohno Dispenser’s ability to maintain a stable flow rate makes it ideal for applications requiring exacting standards of fluid control.

is the registered trademark of HEISHIN Ltd. is the registered trademark of HEISHIN Ltd. |

is the registered trademark of HEISHIN Ltd. is the registered trademark of HEISHIN Ltd. |