This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

For slurry testing of a variety of anode and cathode materials / There are inevitably many bubbles formed during the solid-liquid

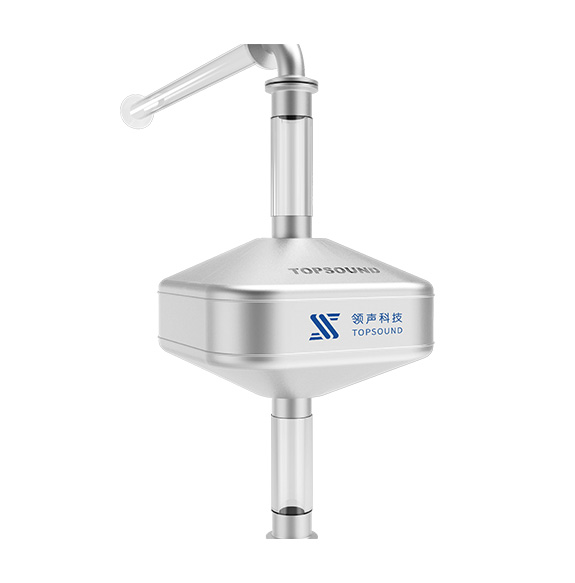

Inline Battery Slurry Quality Detection and Monitoring System

Model:

TOPS-SLU (Detectable Slurry Types : LFP/NCM/NCA/Graphite)

Maker:

Wuxi Topsound Technology Co.,Ltd (Topsound)

Feature

- contact and slurry homogenate process. Bubble bursting during coating

may cause quality problems such as pits and white spots.

leading to local failure and seriously affecting battery capacity,

cycle life, and safety. - Debubbling quality testing is conducted before slurry flows into

the finished product tank after debubbling, and the slurry quality

is automatically determined based on set conditions to decide

whether to perform secondary debubbling or flow into

the finished product tank before coating.