This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

Motor Torque Meter System

Dynamometer using a reliable hysteresis brake with superb reproducibility unaffected by inertia Improved measurement accuracy and ease of use.

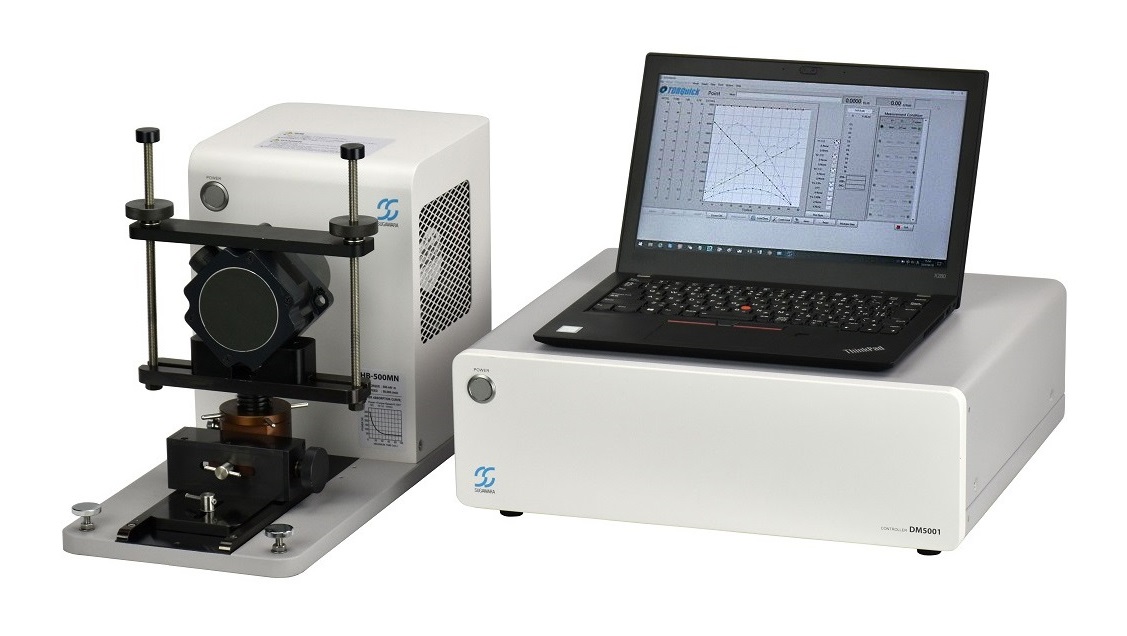

DM5001 Controller/HB series Dynamometers

Model:

DM5001

Maker:

Sugawara Laboratories Inc.

■Performance has been greatly improved

- ・Torque accuracy ±0.1%

- ・Rotation speed accuracy ±0.01%

- ・Maximum rotation speed 60,000 rpm(HB-50MN/100MN/200MN)

■More useful and functional

- ・Simultaneous measurement of motor coil temperature, air motor air flow rate, etc. (optional)

- ・The timing of changes in torque, speed and braking can be freely controlled

- ・External power supplies etc. can be automatically switched on and off at the start and end of measurements (optional)

- ・Analog torque and rotation speed outputs provided as standard

- ・Curve fitting function can be applied to all curves

- ・Enables extrapolation of no-load and stall point data from the measured data

■Better usability

- ・Four measurement units can be connected with a single controller

- ・Simple start-up without the need for PID settings

- ・Torque calibration can be performed on a PC screen

- ・Compatible with Yokogawa WT5000 (∗1)/WT1800E/300E series and Hioki PW3390/PW3335/PW3336/PW3337 power analyzers

- ・Pre-load function to avoid excessively high rotation speeds

(∗1) Select “WT1800E” in the “WT Compatible Command Type Setting” of WT5000. Up to six elements can be used.

■Accurate measurements without inertial effects

In the point measurement mode based on our own control method, the time taken for the motor speed to stabilize (the “wait time”) can be set to eliminate the effect of the moment of inertia on the load torque value and rotation speed. And in the sequence measurement mode used for dynamic measurements, it is possible to minimize the effect of inertia on measurements by using correction values obtained through simple operations

■Torque control without PID parameter setting

Setting up the conventional dynamometers involves adjusting a different set of P, I and D values for each motor being measured, which requires a knowledgeable and experienced operator. In Sugawara’s unique torque control method, there is no need for PID parameter setting. To obtain unambiguous data, all you have to do is fix the motor and shaft correctly and set up the points where torque or rotation speed measurements are to be made. The results will be the same no matter who performs the measurements.

■Four advanced measurement modes

Four measurement modes can be selected to suit each application.

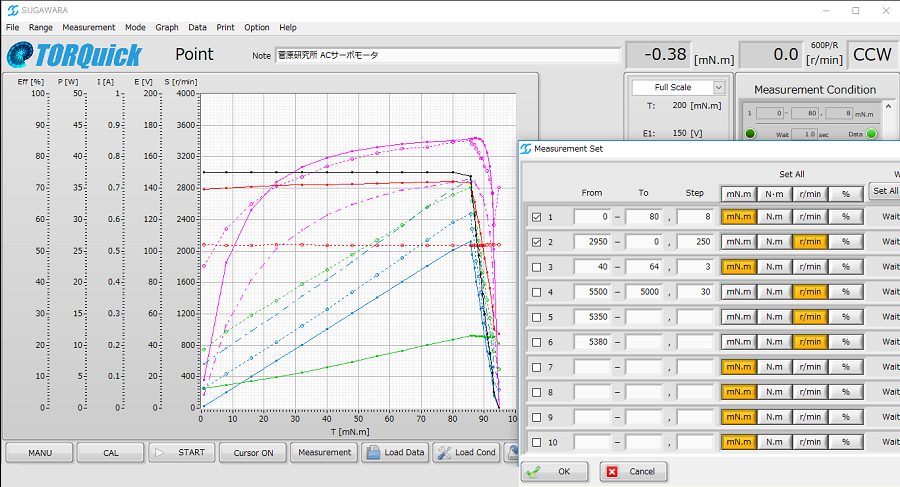

- ・High accuracy point mode with simple settings

You can easily measure the S-T (rotational speed-torque) characteristics simply by setting the measurement points. Torque control, rotational speed control and brake control can be combined in one measurement. The data is not affected by moment of inertia because it measures the value at a stable operating point.

You can easily measure the S-T (rotational speed-torque) characteristics simply by setting the measurement points. Torque control, rotational speed control and brake control can be combined in one measurement. The data is not affected by moment of inertia because it measures the value at a stable operating point.

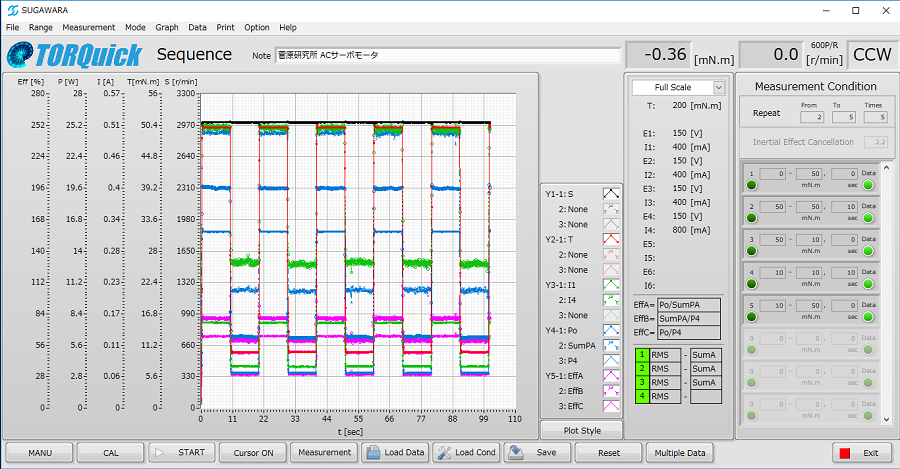

・Sequence mode with support for various types of measurement

By controlling the torque, rotation speed and braking over time, it is possible to perform various tests such as sweep measurements, endurance tests and cycle tests. This makes it possible to perform load simulations based on actual use conditions, and durability tests that combine test conditions and idling conditions and repeat it up to 10,000 cycles.

By controlling the torque, rotation speed and braking over time, it is possible to perform various tests such as sweep measurements, endurance tests and cycle tests. This makes it possible to perform load simulations based on actual use conditions, and durability tests that combine test conditions and idling conditions and repeat it up to 10,000 cycles.

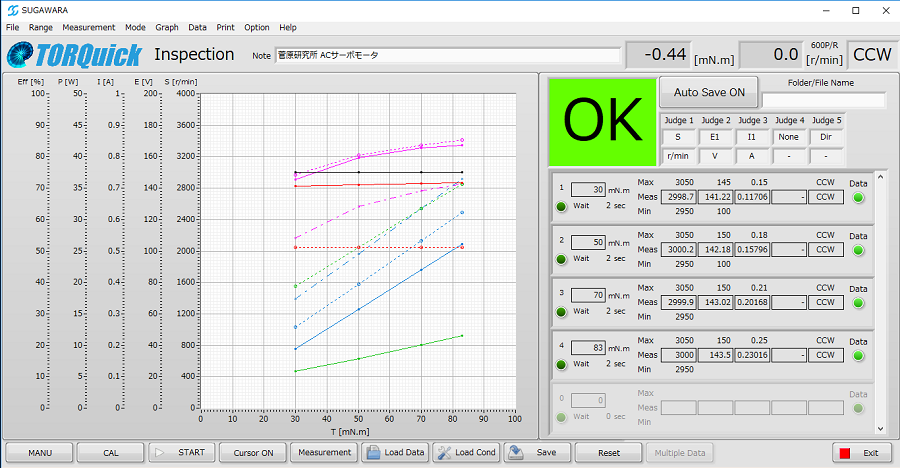

・Inspection mode specialized for pass/fail testing

Pass/fail testing can be performed by setting up to five upper and lower limits for measurement items based on torque, rotation speed or braking. By specifying a file name in advance, you can automatically generate a file listing the time, sequence number and results of each measurement.

Pass/fail testing can be performed by setting up to five upper and lower limits for measurement items based on torque, rotation speed or braking. By specifying a file name in advance, you can automatically generate a file listing the time, sequence number and results of each measurement.

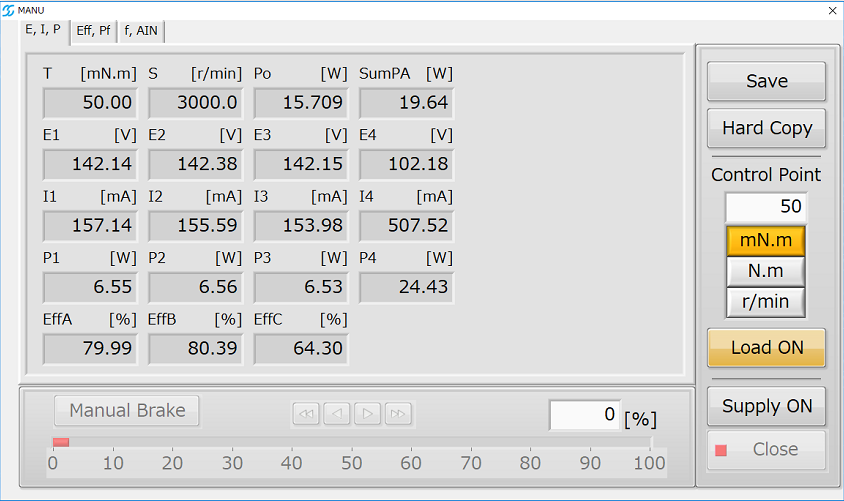

・Manual mode where measured values are displayed in real time

In this mode, you can set and control the torque, rotation speed or braking at a single point, and display all the corresponding measured values in real time. This mode can be used for simple behavior observations and for the measurement of starting torque.

In this mode, you can set and control the torque, rotation speed or braking at a single point, and display all the corresponding measured values in real time. This mode can be used for simple behavior observations and for the measurement of starting torque.

■Additional I/O options for versatile functionality

The addition of extra I/O options provides you with various extended functions.

・Simultaneous measurement of voltage signal input from external sensor

Using an analog 4ch input (0–10 V), it is possible to simultaneously measure and store voltage inputs from external sensors such as temperature and flow rate sensors. The scaling and unit of these inputs are user configurable. These input signals can be plotted simultaneously on a graph of torque measurements and can also be configured as pass/fail judgment criteria.

・Control an external motor power supply

This function allows you to switch a motor’s power supply on and off (via contact inputs). Also, if you use a power supply that has an analog input, the analog voltage output function allows you to change the power supply voltage during the measurement sequence.

■User-friendly graphical user interface

The graph displays 5 axes × 3 items in real time. We have improved the operability of this display by adding a graph axis auto setting function. You can also customize the graph line style and dot appearance.

It is also easy to change the power analyzer settings in software.

■LabVIEW software that can easily be customized

The dedicated TORQuick software is written in LabVIEW and can be flexibly adapted to diverse requirements. Please contact our sales department for further details.

■HB series dynamometers

We have improved the torque measurement accuracy of the hysteresis brake to ±0.1%. A total of 13 models are available, with rated torques ranging from 5 mN·m to 50 N·m. The three models with maximum torque of 50 mN·m, 100 mN·m and 200 mN·m can attain a world-class no-load rotation speed of 60,000 rpm due to our high-precision processing.

Input power measurement compatible with diverse power meters

DM5001 is compatible with the following power meters for voltage and current measurements.

Yokogawa Test & Measurement Corporation

WT5000 (∗1)

WT1800E Series

WT310/WT330/WT300E series

HIOKI E.E. CORPORATION

PW3390/PW3335/PW3336/PW3337

You can choose a suitable one according to your application such as single-phase AC/DC motors and inverter motors.

Video demonstration

Features of DM5001 Controller and HB series Dynamometers

| Torque measurement | Sampling rate:1 ms (16 bit AD converter) |

| Averaging:100 ms moving average | |

| Torque accuracy:±0.1% of full scale (accuracy of the system including DM5001 Controller, after calibration) | |

| Rotation speed accuracy | ±0.01% ±2digit |

| Load control parameter | Torque control:Servo-control of torque value |

| Speed control:Servo-control of rotation speed | |

| Brake control:Open-loop control of brake current | |

| Output power | T[N・m]×S[r/min]×0.1047 |

| Voltage, current, power, efficiency, power factor, and frequency | Measured by a connected power meter |

| Power meter | Yokogawa Test & Measurement Corporation |

| WT5000 (∗1) | |

| WT1800/WT1800E series | |

| WT310/WT330/WT300E series | |

| HIOKI E.E. CORPORATION | |

| PW3390/PW3335/PW3336/PW3337 | |

| Analog output | Torque analog output:±10 VDC/Torque range full scale ±1% |

| Speed analog output:±10 VDC/Speed range full scale ±1% | |

| Options of DM5001 | I/O option |

| Digital input 4ch, Digital output 4ch | |

| Analog input 4ch, Analog output 2ch | |

| Contact output for power supply control (NO, NC)1ch |

| Controller | DM5001 |

| Power | 100-240 VAC, 50/60 Hz |

| Power consumption | 30 VA |

| Temperatures | 0-40 ℃ |

| Humidity | 20-90 %RH, without dew condensation |

| Dimensions | W × H × D 430 × 148 × 360 mm |

| Weight | 8 kg |

(∗1) Select “WT1800E” in the “WT Compatible Command Type Setting” of WT5000. Up to six elements can be used.