Ensure insulation reliability with impulse winding testers, partial discharge detectors, and integrated QA systems – trusted for EV and industrial motor applications.

Why Motor Coil QA Matters

EV and industrial motors demand high insulation reliability.

Motor coil testing detects insulation weaknesses early, preventing failures and ensuring safety and performance.

❗ Problem – Coil Insulation Failures

Voltage surges, thermal stress, and aging lead to insulation breakdown.

✅ Solution – Advanced Motor Coil Testing

Impulse and partial discharge testing detect defects before failure.

→ Detect weak coil insulation

→ Identify early-stage degradation

→ Complete testing for armature & stator

Motor Coil QA & Safety Testing Solutions

Impulse Winding Testers

Simulate inverter surge to detect weak points in coil insulation.

Impulse winding testers apply surge voltages to evaluate coil insulation and detect winding defects before motor breakdown.

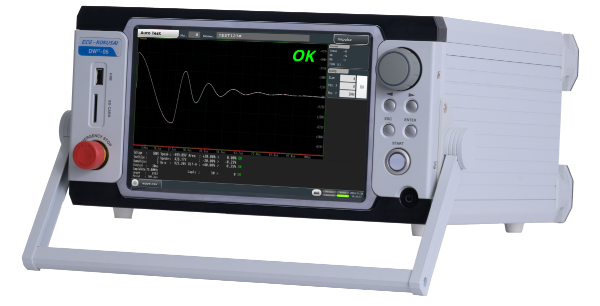

| Model | DWIT-05 | ||||

| Maker | ECG-KOKUSAI | ||||

| Advanced Impulse Tester with PD detection | |||||

| Featuring 5 kV impulse voltage, 300 MHz/12-bit waveform capture, and PD detection, the DWIT-05 delivers high-accuracy, nondestructive coil testing for modern QA teams. | |||||

| Model | DWX-15 | ||||

| Maker | ECG-KOKUSAI | ||||

| Reliable Surge Testing | |||||

| Up to 15 kV impulse testing with 100 MHz sampling—DWX-15/DWX-15PD delivers reliable insulation and partial discharge (PD) detection for motor and coil QA. | |||||

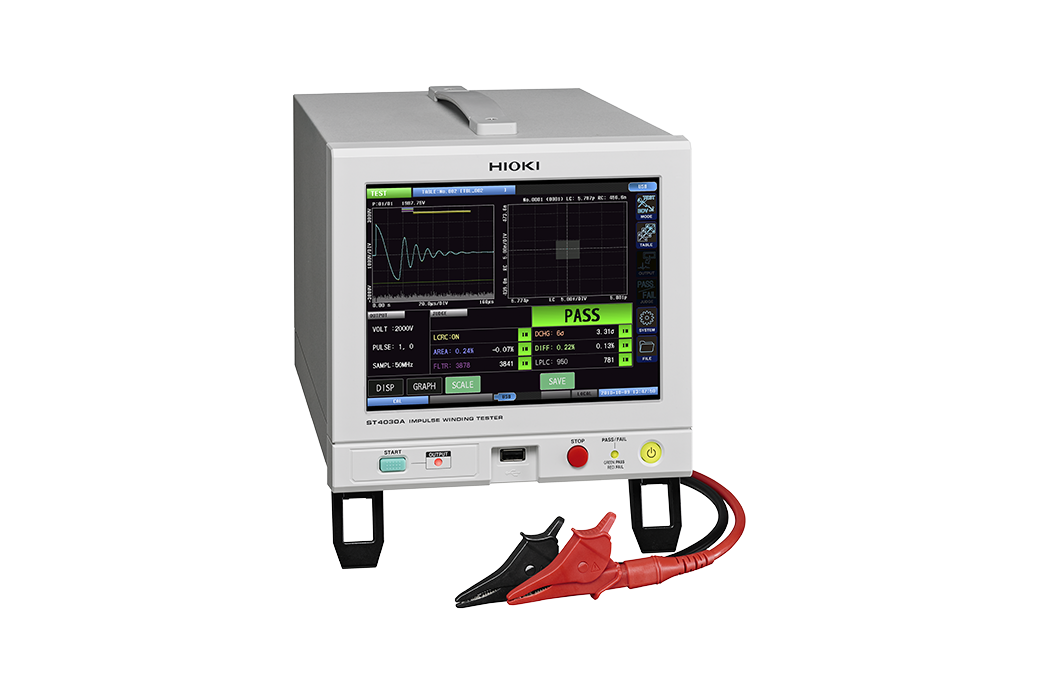

| Model | ST4030A | ||||

| Maker | HIOKI | ||||

| High-resolution Impulse Winding Tester | |||||

| Engineered for EV motors, the ST4030A combines 4,200 V impulse testing with 200 MHz/12-bit waveform analysis to identify single-turn faults and hidden insulation defects. | |||||

Partial Discharge Testing

Detect micro-defects in insulation before complete breakdown.

Partial discharge testers identify early-stage degradation, preventing failures and ensuring motor coil safety.

| Model | DWIT-05*PD | ||||

| Maker | ECG-KOKUSAI | ||||

| Advanced Impulse Tester with PD detection | |||||

| Combines surge testing with PD measurement to evaluate coil insulation under inverter-like stress. | |||||

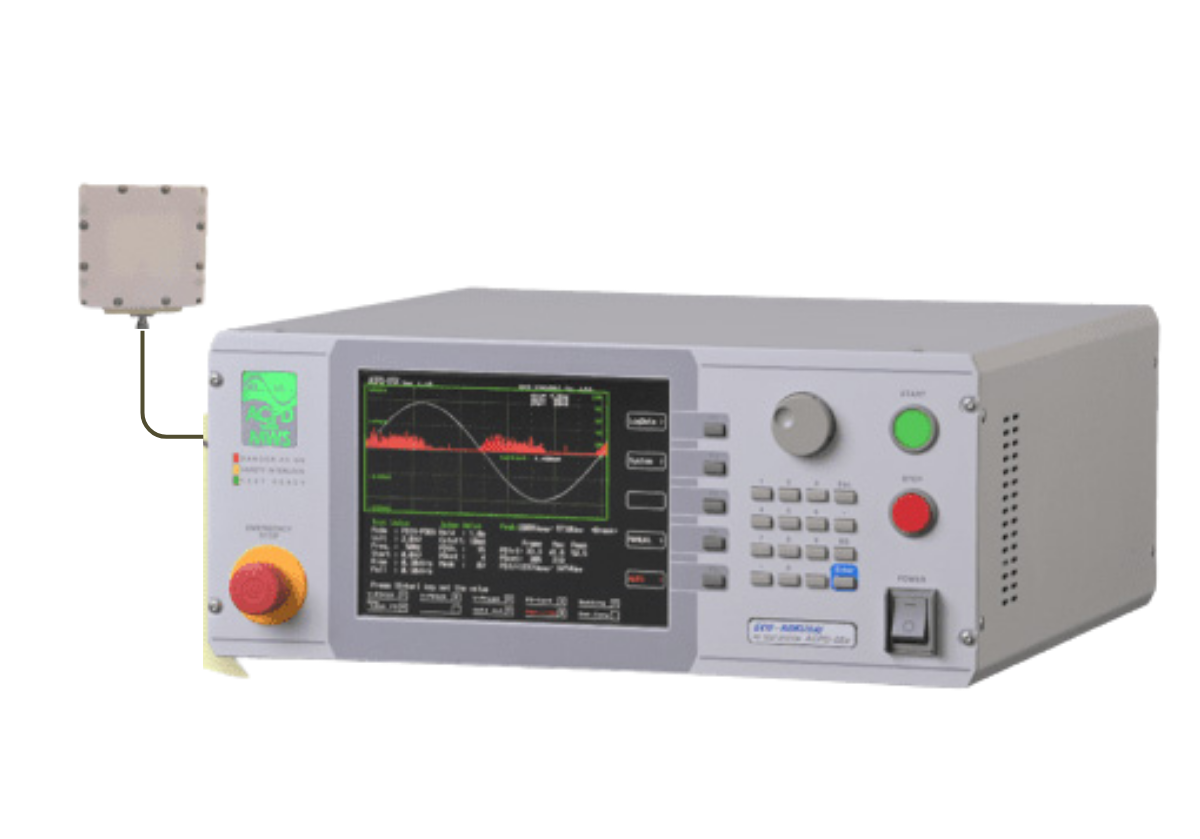

| Model | ACPD-05X | ||||

| Maker | ECG-KOKUSAI | ||||

| AC Partial Discharge Test System | |||||

| Simulates AC operating conditions to evaluate insulation durability. | |||||

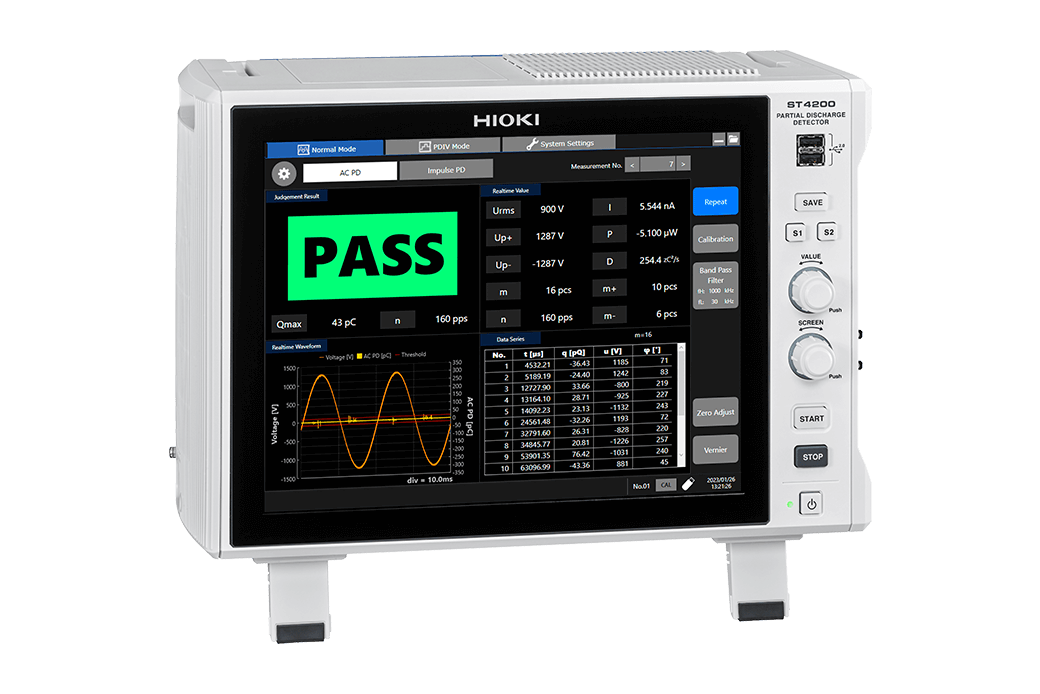

| Model | ST4200 | ||||

| Maker | HIOKI | ||||

| Partial Discharge Detector | |||||

| Sensitive detection of PD events for research and QA environments. | |||||

Integrated Coil QA Systems

Comprehensive QA for armature and stator coils in production lines.

Integrated coil QA systems support end-to-end testing for motor manufacturing, ensuring every coil meets safety and performance standards.

| Model | Armature Coil Test System | ||||

| Maker | ECG-KOKUSAI | ||||

| Armature Coil Test System | |||||

| Automates insulation and winding checks for armature coils. | |||||

| Model | Stator Coil Test System | ||||

| Maker | ECG-KOKUSAI | ||||

| Stator Coil Test System | |||||

| Complete QA solution for stator coils in EV and industrial motors. | |||||

Applications of Motor Coil QA Solutions

🚙Automotive & EV Motors – High-voltage insulation safety

🏭Industrial Motors – Reliability and preventive QA

🥼 R&D Labs – Detect coil degradation early

Why Choose Denkei Americas

-

Authorized distributor of ECG KOKUSAI & HIOKI

-

Local U.S. presence with global Nihon Denkei network

-

Expertise in motor coil QA & safety solutions