This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

HIOKI Powder Impedance Measurement System

Request a Quote

Hioki's Powder Impedance Measurement System provides a comprehensive solution for evaluating powder materials in solid-state batteries within a glove box environment. It features a compact design with integrated compressing and thickness measurement mechanisms to deliver accurate data on impedance, conductivity, and more while ensuring safe operation. With flexible AC/DC resistance measurement, the system supports a wide frequency range. In-house software facilitates data analysis, making rapid property evaluation possible.

Powder Impedance Measurement System

Maker:

The Four Key Benefits of This Product

1. All-in-One Functionality

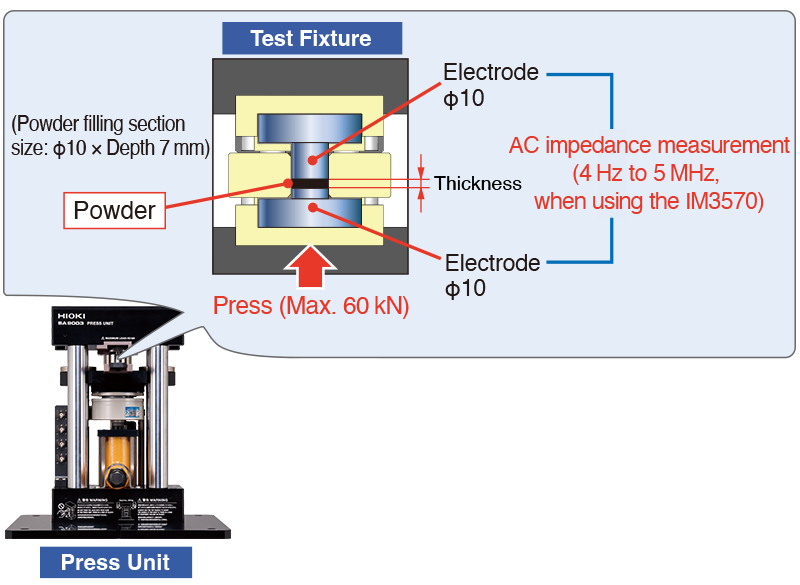

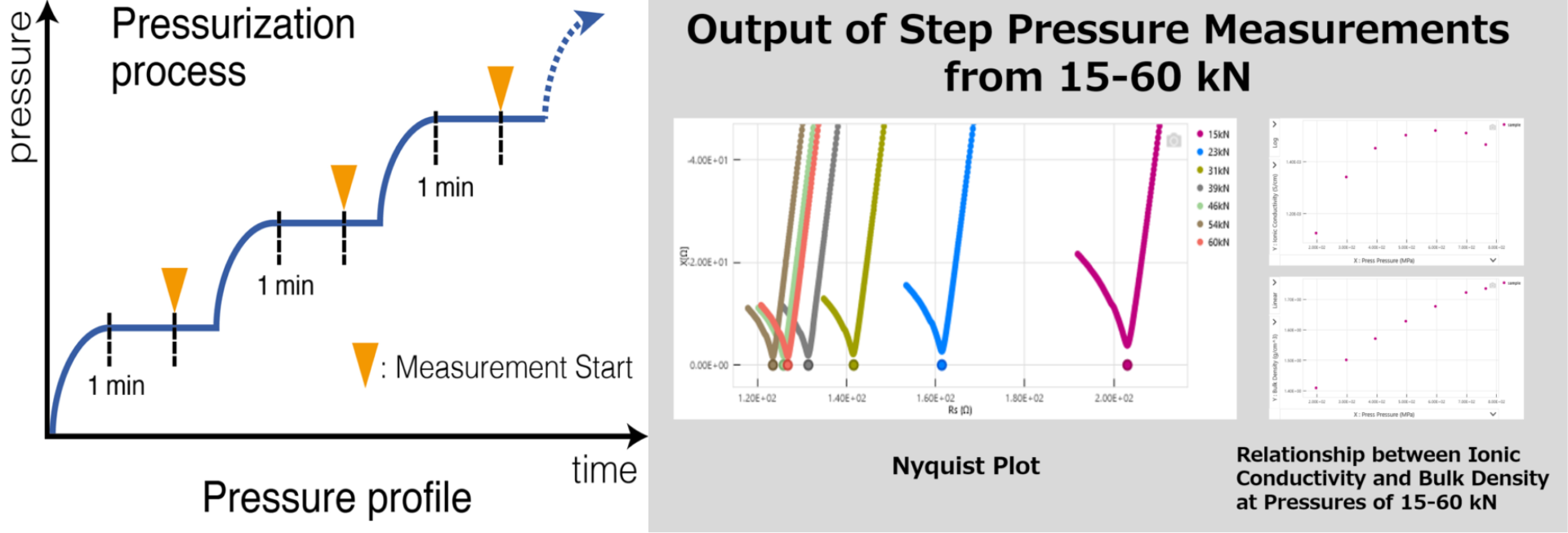

The press unit SA9003, with a maximum press pressure of 764 MPa (using a φ10mm electrode), reliably achieves the pressure conditions expected by users. This system can simultaneously measure impedance, thickness, and pressure while controlling the compression state of powders. Multidimensional analysis using these three critical parameters provides valuable insights into the relationships between bulk density, ionic conductivity, and electrical conductivity. These insights aid in developing solid electrolytes with excellent flexibility, cohesiveness, and resistance to cracking, and also help in determining the optimal material mixing ratio for cathode composites.

*The press unit and test fixture are equipped with the sensors and electrodes needed for measurement, allowing all measurements to be completed simultaneously with the pressing operation.

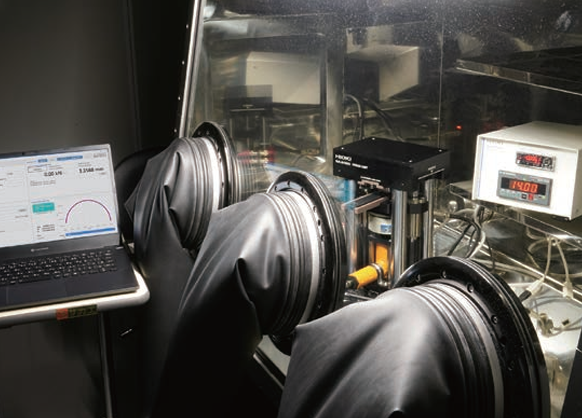

2. Compactness Revolutionizing R&D

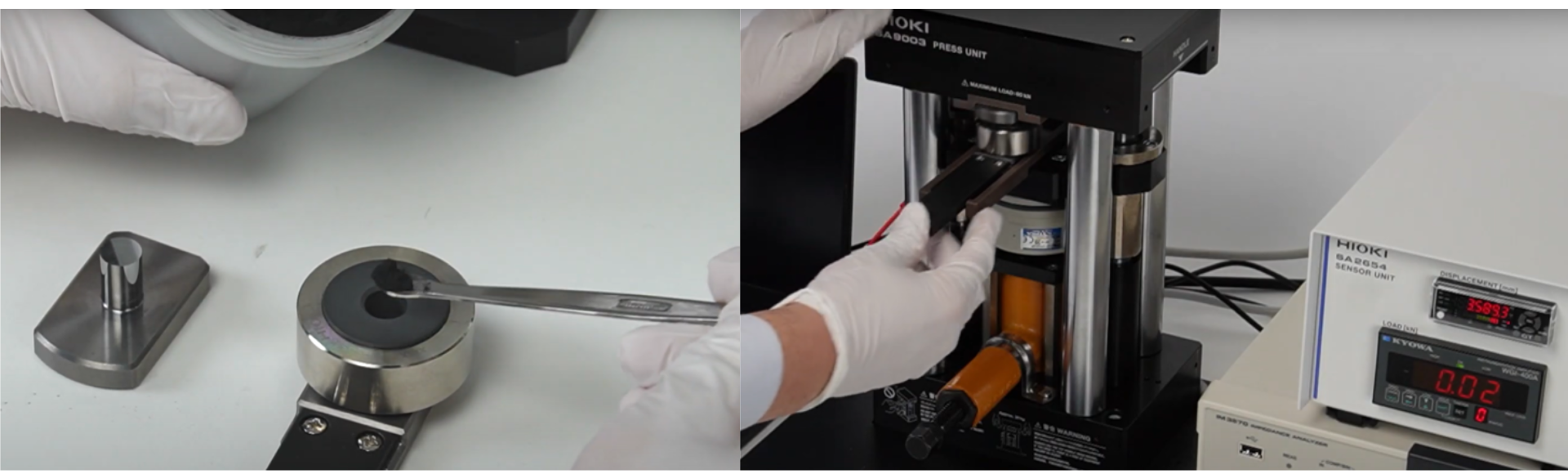

The remarkably compact measurement system can be easily integrated into a glove box. Its compactness ensures it does not encroach on the valuable workspace within the glove box. From filling to compression and measurement, the materials never leave the glove box, meaning they are completely isolated from external moisture.

This allows all processes to be completed in a strictly controlled environment, enhancing the stability and reliability of measurement results. Researchers can eliminate unnecessary tasks and concerns, allowing them to focus confidently on their analysis in a secure research environment.

*The extremely lightweight and compact test fixture and press unit make both the installation and working spaces compact.

3. Eliminating Safety and Degradation Risks for Researchers

Sulfide-based powder materials release harmful hydrogen sulfide gas when reacting with moisture in the air. Halide-based powder materials are highly hygroscopic and can dissolve in moisture. Additionally, many battery materials risk degradation when reacting with moisture.

Currently, researchers invest significant effort into avoiding these risks by filling materials into moisture-blocking sealed test cells and repeatedly moving them in and out of glove boxes. This system allows all processes to be completed within the glove box, freeing researchers from concerns about safety risks and material degradation.

4. Reduce Evaluation Costs and Increase Experiment Trials

To advance research, it is necessary to repeat hypotheses and experiments. Accelerating solid-state battery research requires changing pressure conditions and material ratios to conduct numerous experiments. Traditionally, after compressing powders in a glove box, samples had to be removed for evaluation. Additionally, since samples couldn’t be reused after measurement, one sample was consumed per pressure condition, increasing time and sample consumption, thus raising evaluation costs and hindering increased experimentation.

HIOKI’s Powder Impedance Measurement System completes all processes within the glove box. For example, it can reduce experiment time from over two hours to about ten minutes. Moreover, with the integration of the pressing mechanism and measurement electrodes, continuous measurement with varying pressures on a single sample is possible, significantly reducing sample consumption. Researchers can efficiently utilize limited resources and conduct more experiments.

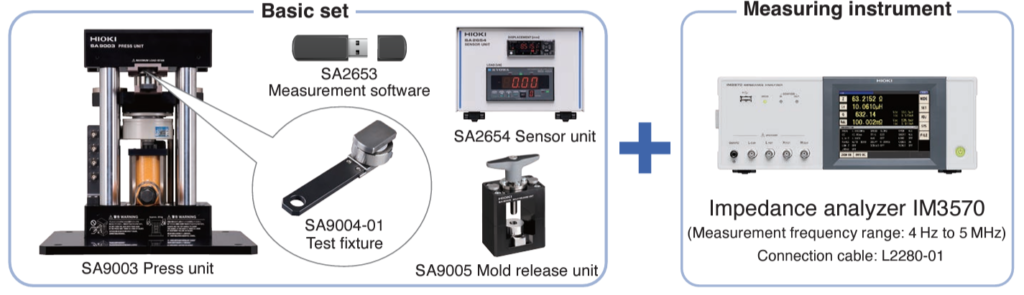

System Configuration

This system is composed of multiple units that simultaneously measure the mechanical and electrical properties of powder materials. The all-in-one compact press unit with various functions allows for continuous measurement under multiple pressure conditions for a single sample.

・A compact press unit equipped with a pressing mechanism and sensors for measuring thickness and pressure

・A high-strength test fixture with electrodes for filling powder materials

・An impedance analyzer for measuring electrical parameters

・A sensor unit for monitoring mechanical parameters

・Intelligent integrated software for comprehensive analysis of the measurement data