This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

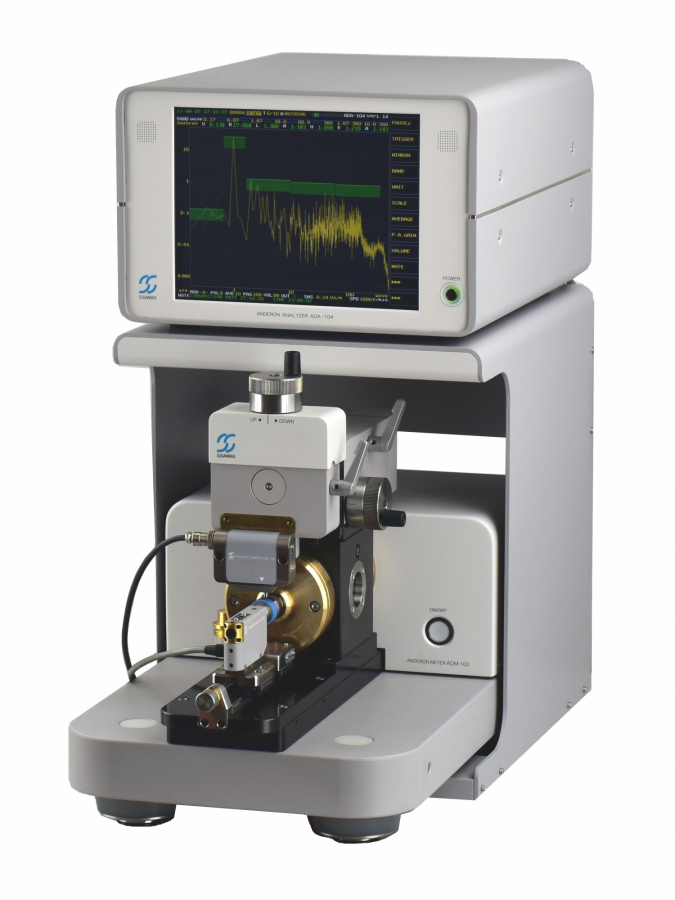

SUGAWARA - Bearing Vibration Tester - Anderon Meter -

[Contact Us]

The Anderon Meter measures bearing vibration to enhance efficiency and reduce noise in motors and home appliances. It rotates the inner ring at 1800 r/min with precise sensors detecting outer ring vibrations. This pre-screening tool grades bearings, improving device performance and lifespan with FFT analysis of vibration signals.

Feature

・Accurately measures bearing vibration levels and quantifies this in Anderon units (*1) at high levels of reproducibility.

・By changing attachments, a single Anderon meter can be used to measure bearings ranging from ultra-small (with an inner diameter of 1 mm), to medium-sized (with an outer diameter of 100 mm).

・Conforms to the measurement conditions specified in ISO15242-2:2015.

・The use of a fluid dynamic spindle ensures background noise of 0.1 Anderon or less (= 0.77 μm/s or less).

・The proprietary Pusher (a device that applies axial load to the outer ring) does not require any specific skills by the person performing the measurements. The obtained data are always highly reproducible.

・The compact design allows for a table-top set-up.

(*1: The Anderon meter was proposed by Chaney et al. from the U.S. in a 1944 paper as a device for measuring the vibration of rotating bearings. The “Anderon measurement” and “Anderon value” defined in this paper are the most standardized concepts for evaluating bearing vibration characteristics.

Bearing Quality Control Through Use of Anderon Meter

Abnormal noise emanating from rotational equipment using rolling bearings is generated by the damage or contamination of those bearings. This type of noise can be prevented by screening bearings before incorporating them in the device. The reduction of device rejection rates through the prior screening of bearings has a major financial effect.

Measuring a few hundred bearings used in a device will clarify the standard for the truly tolerated vibration level of the bearings incorporated in that device.

– Achieving increased precision –

Grade the bearings by vibration characteristics (Anderon value + peak characteristics). Perform abnormal noise tests on devices incorporating these graded bearings, and study the correlation between test results and used bearings. This makes it possible for the bearing vibration characteristics required for a device to be determined with accuracy.

Learn more

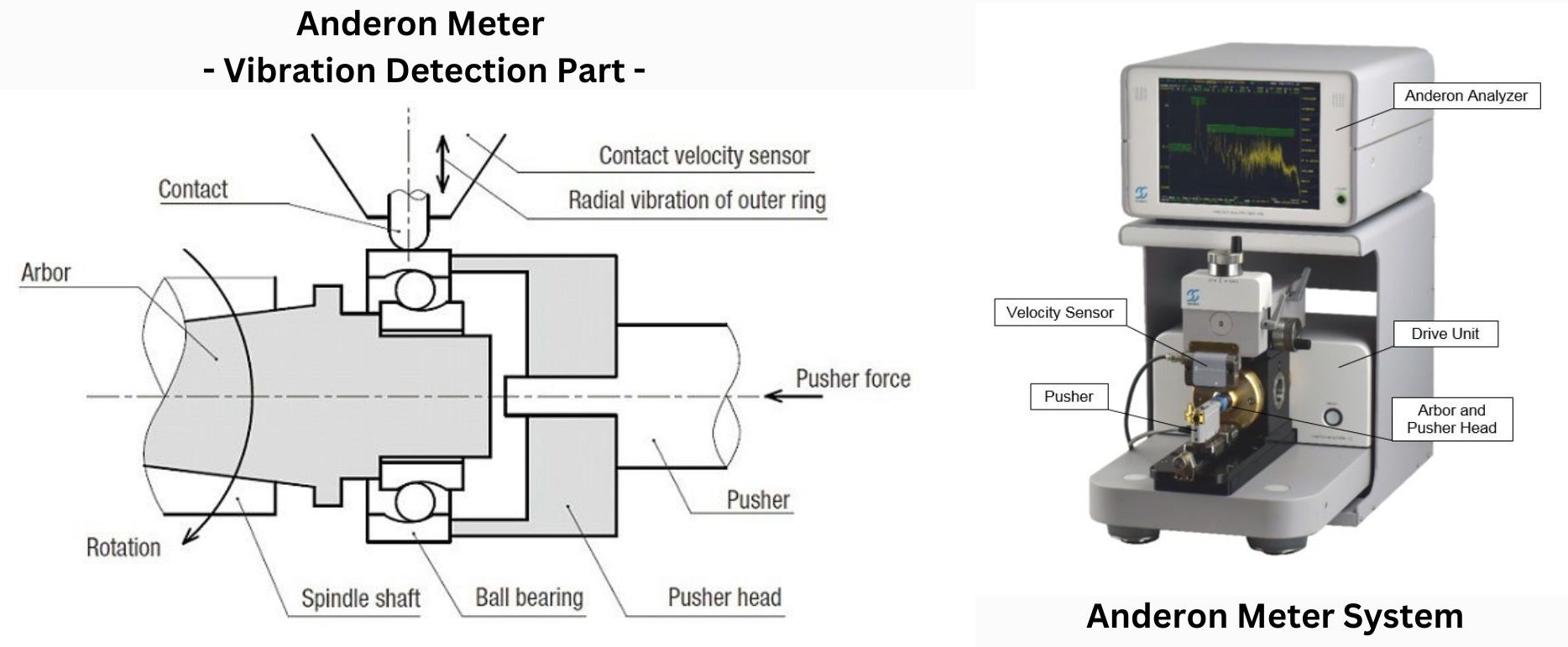

Vibration Detection Principles

An Arbor, designed so that its tip matches the inner diameter of the bearing to be measured, is fitted to the spindle, and the spindle is rotated at 1800 r/min. The bearing inner ring is inserted into the Arbor tip, and the inner ring is rotated at 1800 r/min.

A Pusher Head, designed to match the outer diameter of the bearing to be measured, is fitted to the Pusher. By applying force on the outer ring in the axial direction with the Pusher, the rotation of the outer ring is stopped.

A situation is thus created where the inner ring rotates while the outer ring does not. By bringing a probe into contact with the surface of the outer ring, which is not rotating, the degree of vibration in the radial direction of the outer ring is detected.

System Configuration

Drive Unit

Rotates the inner bearing ring using the Arbor.

Pusher

Applies axial load onto the outer ring using the Pusher Head, and stops the rotation of the outer ring.

Velocity Sensor

Brought into contact with the outer ring surface to detect vibration in the radial direction.

Anderon Analyzer

Applies an FFT analysis to velocity sensor signals and digitizes them for each band.

Arbor and Pusher Head

One Arbor is required for each bearing inner diameter size, and one Pusher Head for each outer diameter size.

Anderon Meter - Video Guide

Specifications

| Bearing size range | Drive Unit ADM-104: Bearing inner ring bore 1 mm to outer ring diameter 100 mm Drive Unit ADM-709: Bearing inner ring bore 10 mm to outer ring diameter 220 mm |

||||||

| Bearing type range | Deep groove ball bearings Angular contact ball bearings Self-aligning ball bearings Tapered roller bearings Spherical roller bearings Cylindrical roller bearings (Drive Unit ADM-709-U1) |

||||||

| Measurement frequency bands | Seven standard bands (U, R, L, M, H, E, A Band) L band: 1.67 – 10.0 wave (50 – 300 Hz) M band: 10.0 – 60.0 wave (300 – 1800 Hz) H band: 60.0 – 360 wave (1800 – 10000 Hz) |

||||||

| Pusher force (axial direction) | Drive Unit ADM-104 ADP-20NX: max 20 N ADP-200NX: max 200 N Drive Unit ADM-709 ADP-200NS: max 200 N ADP-2KNS: max 2 kN |

||||||

| Pusher force (radial direction) | Two points, 100 N each (ADM-709-U1) | ||||||

| Spindle speed | Drive Unit ADM-104: 1800 r/min Drive Unit ADM-709: 300-3600 r/min, adjustable |

||||||

| Spindle bearing type | Fluid dynamic bearing (oil) | ||||||

| Spindle drive system | Direct drive | ||||||

| Tools for measurement | One Arbor per bearing inner ring bore One Pusher Head per bearing outer ring diameter |

||||||

| Power requirements | Anderon Analyzer ADA-105: 100-240 VAC, 50/60 Hz Drive Unit ADM-104: 100 VAC, 50/60 Hz Drive Unit ADM-709: 100 VAC, 50/60 Hz |

||||||

| Dimension (W × H × D) | ADA-105: 12.40 in × 8.58 in × 11.81 in ADM-104: 11.81 in × 15.20 in × 19.13 in ADM-709: 27.56 in × 52.60 in × 50.39 in |

||||||

| Weight | ADA-105: 22 lbs ADM-104: 176 lbs ADM-709: 992 lbs |

||||||