This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

Medium-size/small-lot production model

Request a Quote

The SZ-2500 is a medium-size model that supports microfabrication to medium-size shaping.

The laser spot diameter is variable in a range of 50 - 300μm, which significantly improves drawing efficiency.

The 3D printing area is as wide as 250 × 250mm, where multiple small-size parts can be created simultaneously.

It is a versatile model that supports research & development through small-lot production.

Features

-

1.High-efficiency Microfabrication: The adjustable laser spot diameter (50–300 μm) enables precise and efficient drawing, supporting both fine and medium-size fabrication.

-

2.Large Build Area: With a 250 × 250 mm printing area, it allows for simultaneous production of multiple small parts.

-

3.Versatile for R&D and Small-lot Production: Ideal for research and development as well as small-scale manufacturing needs.

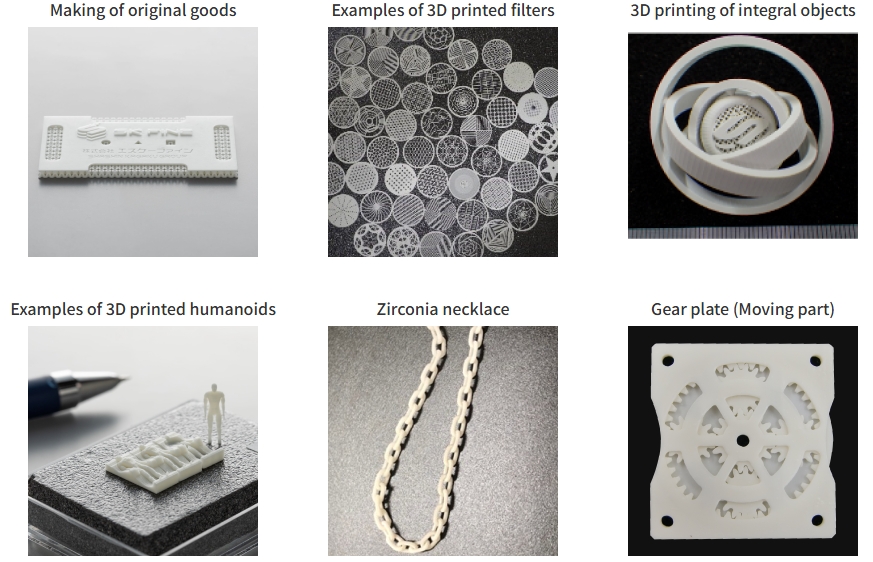

Application Examples

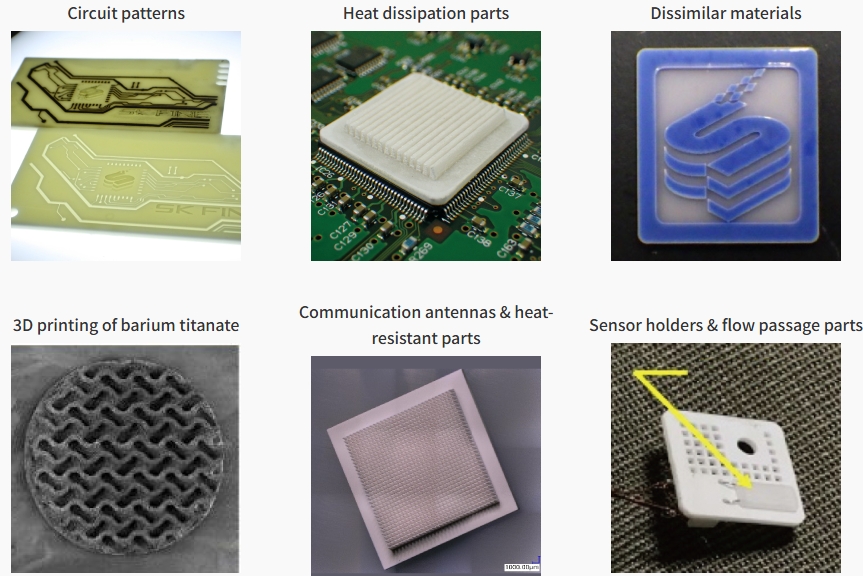

1.Electric & electronic parts

The SZ series can reproduce distinctive shapes specific to 3D printing with ceramics. Functionality can be improved by the structure, such as weight reduction and heat dissipation of ceramic members. Since laminated layer height differences increase the surface area, it is expected that the functionality of catalysts, etc., will improve. High-efficiency electrodes, gas sensor devices, and others can be made of functional ceramic materials.

2.Biological & medical systems

The SZ series is also compatible with biocompatible materials, so that artificial bones having a sponge body structure, dental materials, etc. can be made. It also possible to prototype parts of medical devices as ceramics are substituted for metals.

The chemical resistance, heat resistance, and allergic resistance of ceramics are effective for medical care.

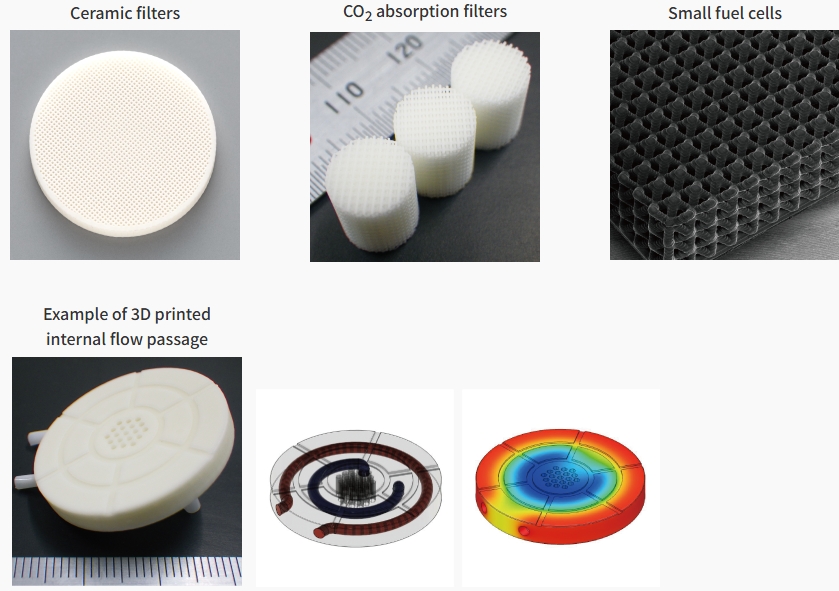

3.Energy & environment systems

The SZ series realizes improvement in catalytic function by expanding the surface area through utilization of laminated layer height differences specific to 3D printing, and higher added value by optimizing the materials and functions, such as flow passage design with unique shapes.

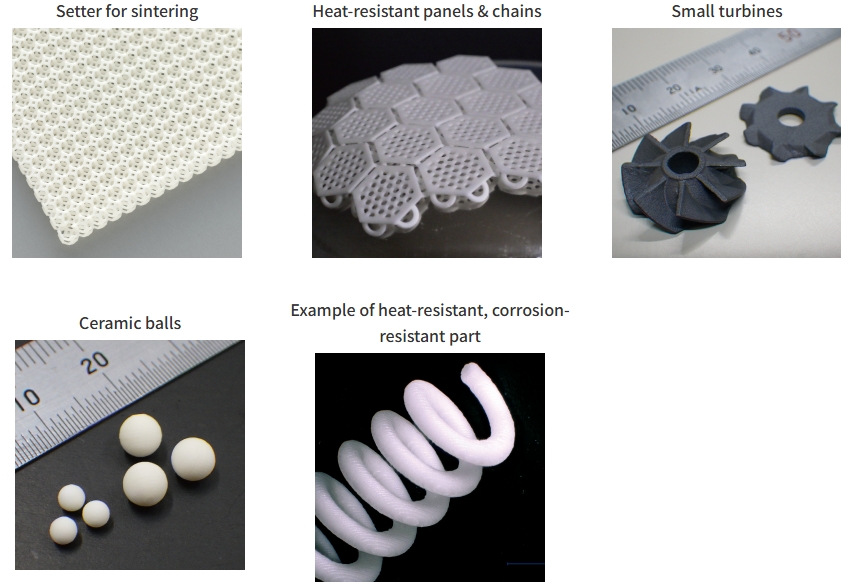

4.Mechanical parts & heat dissipation parts

The SZ series allows for use of the same materials as ceramic injection molding (CIM). It is suitable for making of prototype models before mass-production, small-lot production, and production of complex shapes for which molds are expensive. It is effective for prototyping to evaluate the functionality of actual materials according to structural differences, etc. Also, 3D printing excels in cost performance with increasingly microscopic and complex shapes.

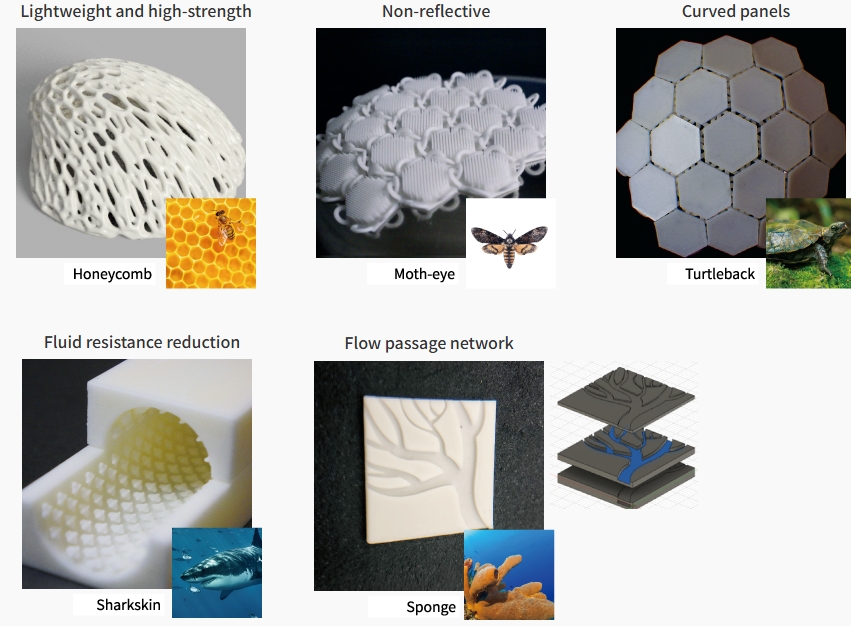

5.Biomimetics

There are many cases where living things improve their functionality due to special shapes.

They can also be realized with ceramics by microscopic 3D printing technology of the SZ series.

6.Accessories & single items

The SZ series can shape one-of-a-kind items with ceramics by taking advantage of the degree of freedom of 3D printing.

Originally designed tools and accessories can be made.

When created with zirconia, etc., even ceramics can be made into accessories, realizing such complex shapes.