This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

Shashin Kagaku DLP type 3D printer Standard model SZ-800

[Contact Us]

The SZ-800 is a standard model developed to realize easy operation, quick and precise modeling with DLP one-shot exposure for research and development use.

Wavelength is selectable from 365nm and 405nm to enhance flexibility of material choice.

Equipped with functions specific to a mass-production machine

・ Equipped with an external large-capacity automatic slurry replenishment unit, which enables long-time continuous operation without running out of materials.

・ Equipped with surveillance cameras that monitor defects during 3D printing.

・ Equipped with the functions of blade cleaning and surplus slurry recovery, which enable effective use of surplus materials in 3D printing.

・ Equipped with a conveying table that smoothly carries out a green body on the stage to the cleaning process after large-area 3D printing.

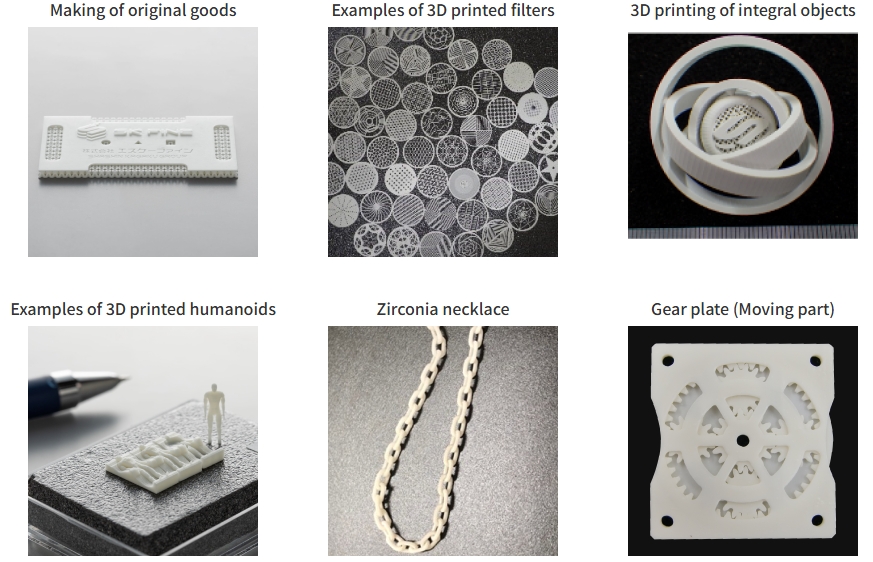

Application Examples

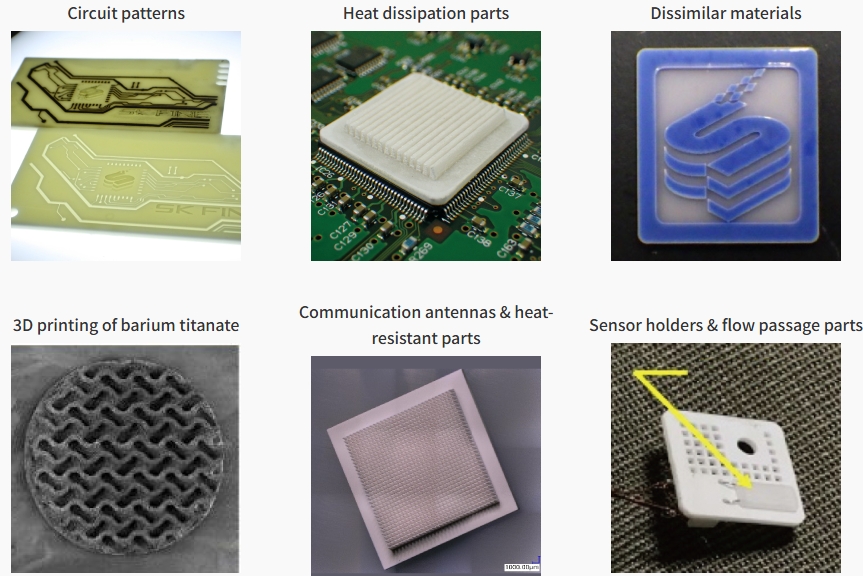

1.Electric & electronic parts

The SZ series can reproduce distinctive shapes specific to 3D printing with ceramics. Functionality can be improved by the structure, such as weight reduction and heat dissipation of ceramic members. Since laminated layer height differences increase the surface area, it is expected that the functionality of catalysts, etc., will improve. High-efficiency electrodes, gas sensor devices, and others can be made of functional ceramic materials.

2.Biological & medical systems

The SZ series is also compatible with biocompatible materials, so that artificial bones having a sponge body structure, dental materials, etc. can be made. It also possible to prototype parts of medical devices as ceramics are substituted for metals.

The chemical resistance, heat resistance, and allergic resistance of ceramics are effective for medical care.

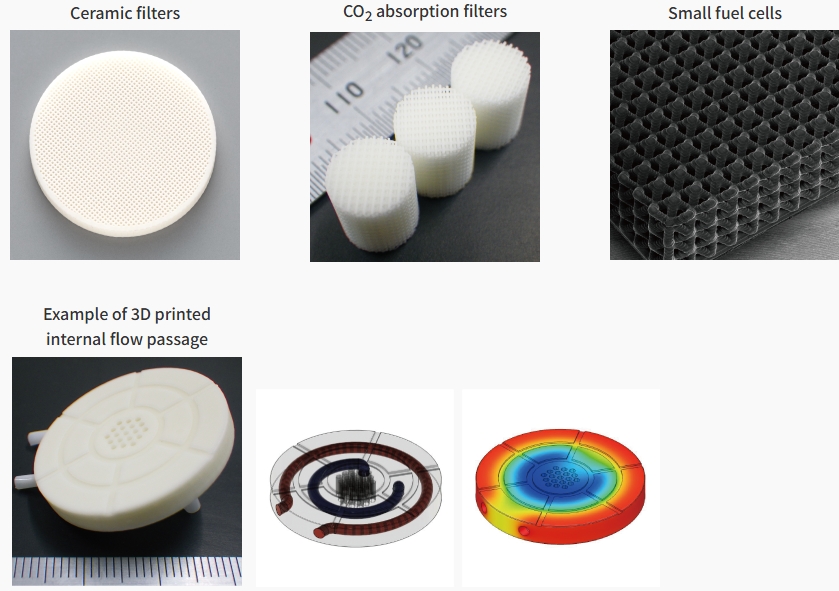

3.Energy & environment systems

The SZ series realizes improvement in catalytic function by expanding the surface area through utilization of laminated layer height differences specific to 3D printing, and higher added value by optimizing the materials and functions, such as flow passage design with unique shapes.

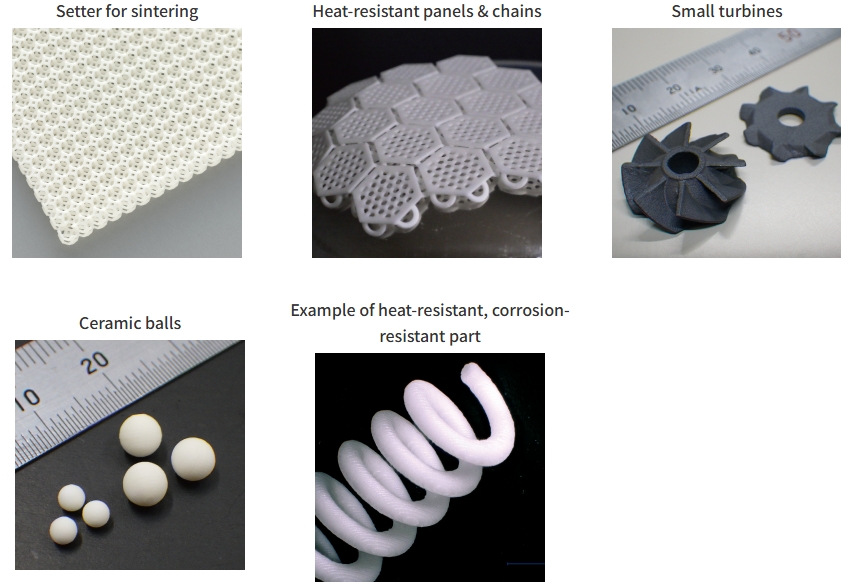

4.Mechanical parts & heat dissipation parts

The SZ series allows for use of the same materials as ceramic injection molding (CIM). It is suitable for making of prototype models before mass-production, small-lot production, and production of complex shapes for which molds are expensive. It is effective for prototyping to evaluate the functionality of actual materials according to structural differences, etc. Also, 3D printing excels in cost performance with increasingly microscopic and complex shapes.

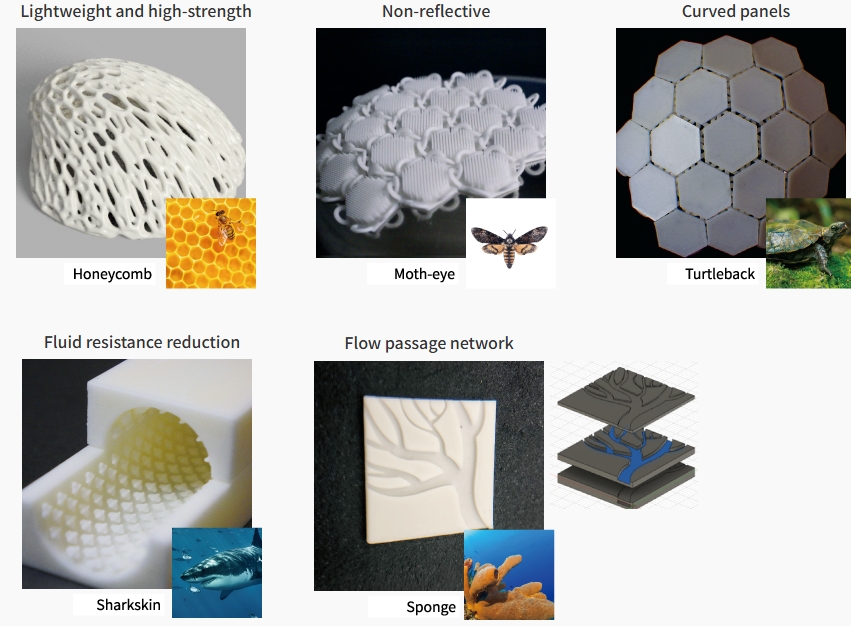

5.Biomimetics

There are many cases where living things improve their functionality due to special shapes.

They can also be realized with ceramics by microscopic 3D printing technology of the SZ series.

6.Accessories & single items

The SZ series can shape one-of-a-kind items with ceramics by taking advantage of the degree of freedom of 3D printing.

Originally designed tools and accessories can be made.

When created with zirconia, etc., even ceramics can be made into accessories, realizing such complex shapes.

Specifications

| Model | Standard model SZ-800 |

| 3D printing area | 80 x 55 x H50mm |

| Layer pitch | 10~200µm |

| Spot diameter | – |

| 3D Printing Resolution | Dot 35µm |

| Output power | – |

| Equipment size | 800 x 900 x H1700mm |

| Power supply | Single phase 200V AC 2A |