This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

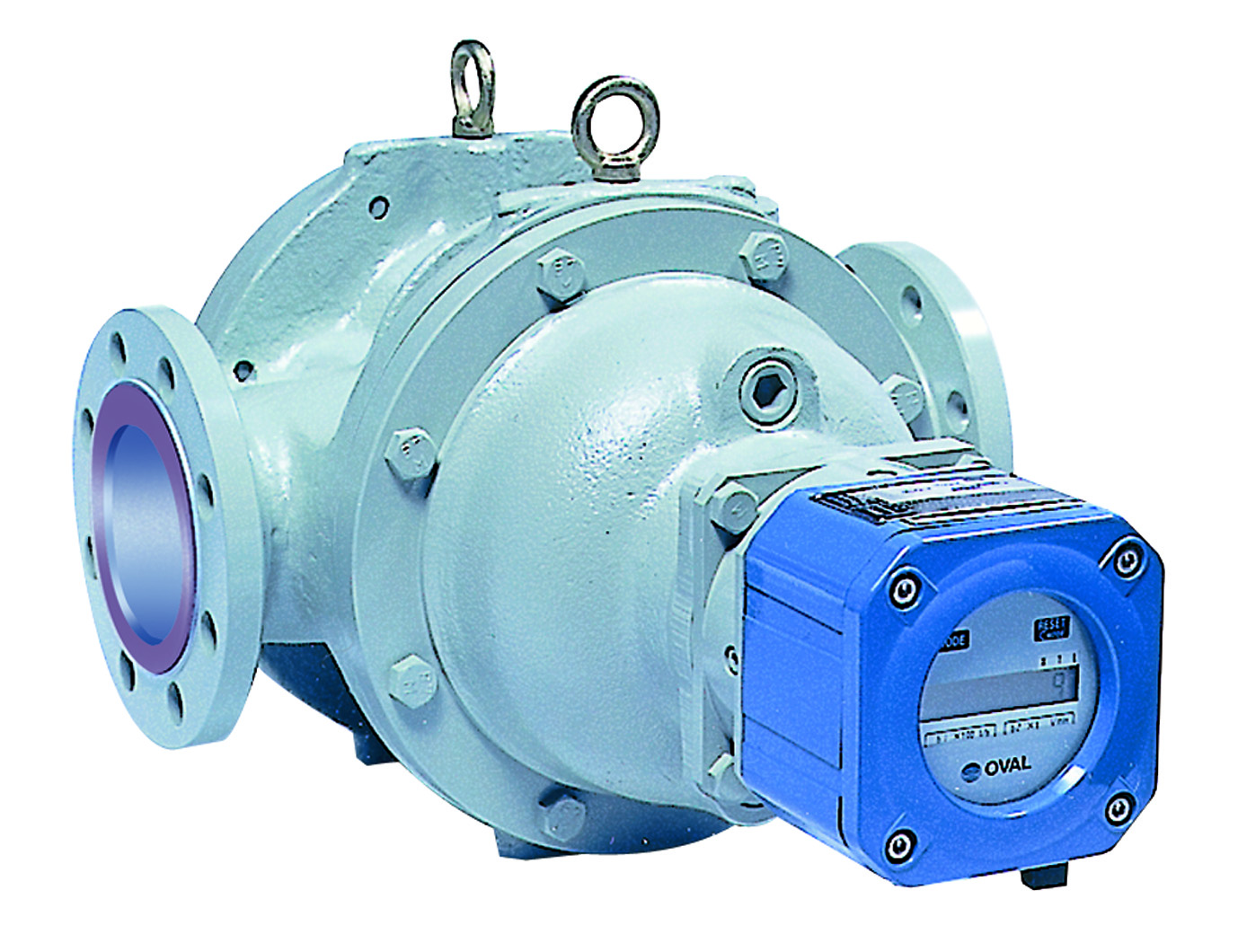

ULTRA UF-Ⅱ Spiral Rotor Flowmeter

Request a Quote

The ULTRA UF-Ⅱ from OVAL is a positive displacement flowmeter featuring a unique spiral rotor design that ensures pulsation-free, low-noise operation with minimal vibration.

Its constant torque and low friction provide durability and high accuracy across a wide range of flow rates.

Ideal for petroleum product transactions, refineries, and tank truck systems, it supports total and instantaneous flow measurement with a multifunction electronic register. Options include explosionproof, high/low temperature, and battery-powered models, with available pulse and analog outputs for advanced monitoring and batch control.

FEATURES

1. Constant rotor rotation speed, constant torque, constant flowrate with no pulsation results in low pressure loss and enables extremely quiet operation with minimum vibration.

2. Less rotor friction of the spiral rotors provides high durability.

3. Large discharge rate per rotation and relatively high rotation speed allows measurement of large volumes even with small nominal size.

4. Simple structure without the need of pilot gears.

5. The ULTRA register equipped with a CPU indicates total flow, resettable total flow, instantaneous flowrate and low battery alarm on the LCD by changing the mode selector.

6. Output signal is available in two channels simultaneously in the form of total flow (4/20 mA DC scaled or unscaled current pulse) and instantaneous flowrate signal (4 to 20mADC analog).

7. A complete series of explosionproof model also available.

8. With batch controller equipped ULTRA register, you can establish a simple batch control system.

Principle of Operation

Having a pair of rotors as revolving elements (see photo at right), the UF-ll is a positive displacement flowmeter which directly measures the volume of flowing fluid passing through. A pair of these spiral rotors are directly in gear with each other specially designed and precisely processed to achieve a zero slip factor. Operation principle is shown in the figure below. As the process fluid flows into the measuring chamber, the rotors are, under a differential pressure that exists between the inlet and outlet, made to rotate in the direction opposite to each other as shown by arrows.

In figure ”A”, viewed on a plane illustration, a rotational force acts only on the first rotor; no rotational force acting on the second. But these rotors in actual are twisted as shown in the photo. Each rotor receives the same rotational force, resulting in uniform rotor rotation and uniform rotational torque with no pulsation in the flow being discharged.

Each space formed by the rotors and the inner wall of the measuring chamber serves as a pocket (colored in blue) and, in one complete rotor revolution, the process fluid of eight times the volume of this pocket is delivered to the discharge outlet. Therefore, taking this rotor rotation by rotational frequency, we can measure the exact total volume of the process material delivered, while the instantaneous flowrate can be measured by the rotational velocity.

Connection with receiver

ULTRA UF-Ⅱ is available in the following types: a battery driven type (without output) that requires no external power supply and an external power supply type (with pulse output and analog output).

Performance Characteristics

GENERAL SPECIFICATIONS

| Model | Electronic Counter (Ultra Counter) | |||

| Nominal size | 80 to 100mm | 100 to 450mm | ||

| Connection standard (Flange) |

JIS 10K | JIS 20K | ||

| ASME 125, ASME/JPI 150 | ASME/JPI 150 | |||

| Flow range* | 8 to 180m3/h (2types) | 17 to 2800m3/h (7types) | ||

| Operating temp. range | –5 to +120°C or 0 to +120°C | –5 to +120°C | ||

| Max. operating pressure |

1.37MPa (Depends on body material) | 1.96MPa (Depends on connection standard) | ||

| Accuracy | Within ±0.2% of reading | Within ±0.5% or ±0.2% of reading | ||

| Power supply | DC-powered or battery-powered | |||

| Output | Analog, pulse | |||

| Configuration | Explosionproof or non-explosionproof, IP66 | |||

| Body material | FC250 or SCPH2 | |||

| Applicable fluids | Water, gasoline, light oil, heavy oil, etc.他 | |||

* 5 to 1000 mPa·s in viscosity