This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

Psonic-L4 Ultrasonic Oil Flowmeter

Request a Quote

The OVAL Psonic-L4 is a high-performance ultrasonic flowmeter designed for custody transfer and accurate petroleum product measurement. Using a parallel 4-path ultrasonic system, it achieves ±0.15% accuracy while ensuring long-term stability and redundancy.

The design enables bi-directional measurement, reducing pipeline layout and installation costs. With no strainer required, running costs are minimized. Extensive self-diagnostics, ISO/IEC17025 calibration traceability, and explosionproof construction make it a reliable solution for critical oil and fuel applications, including gasoline, kerosene, light oil, and heavy oil.

Features

Measurement Principle

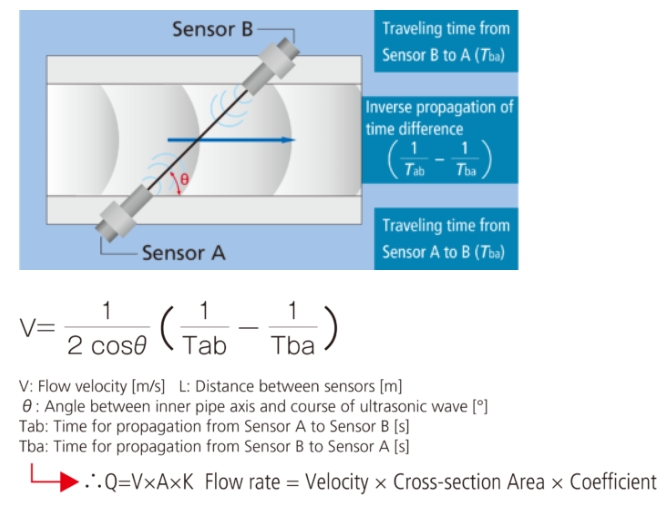

Propagation time and flow velocity (flow rate)

The ultrasonic flowmeter measures the time of ultrasonic wave transmitted from one sensor and received by the other. This time duration is called “propagation time.”

When there is no flow, the propagation time from sensor A to sensor B (Tab) and the propagation time from sensor B to sensor A (Tba) should be the same. However, once the fluid is flowing, ultrasonic signal is affected by the flow, creating a difference between propagation times Tab and Tba. The ultrasonic flowmeter measures propagation times Tab and Tba, then calculates the flow velocity from the difference in propagation times, and provides the flow rate by multiplying the flow velocity by the cross-section area of the pipe.

The parallel path system provides long-term stability and redundancy

Parallel path system allows long-term stability

Small attenuation of ultrasonic waves allows strong signal reception. Compared to the reflection method, ultrasonic waves are less likely to be affected by risks such as dirt inside the pipe.

4-path system provides redundancy

To continue the measurement in case of sensor failure, the Psonic-L4 is capable of supplement processing. The possible downtime can be minimized.

New flowmeter for custody transfer of petroleum products

● Suitable for custody transfer application of petroleum products

● Suitable for custody transfer application of petroleum products

● Capable of bi-directional measurement

● Bi-directional measurement simplifies pipeline layout: lower pipe installation cost

● No strainer required: reduces running cost

Extensive self-diagnostic functions

To achieve superior performance stability as a liquid flowmeter (especially for the measurement of petroleum products), the Psonic-L4 is equipped with extensive self-diagnostic functions.

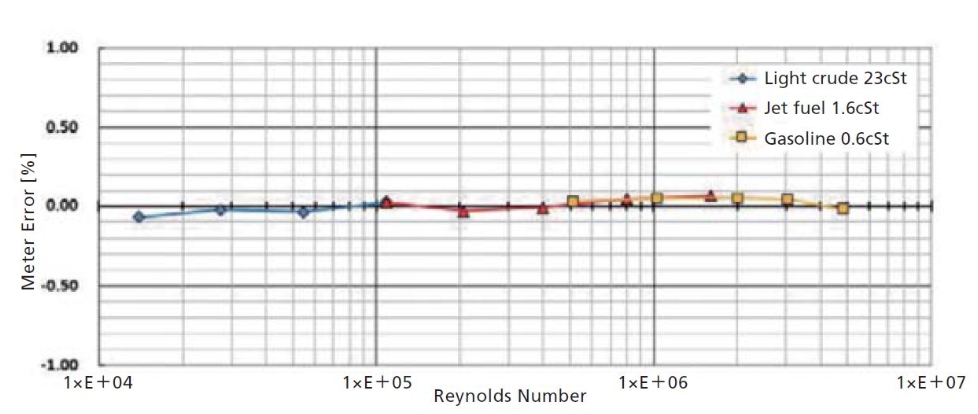

High accuracy: ±0.15%RD

●With its 4-path method, the Psonic-L4 achieved the accuracy of ±0.15%RD.

●Conducting the calibration test at ISO/IEC17025 accredited facility ensures the traceability required in custody transfer applications.

■ Under the condition where an upstream

meter run with flow straightener (10D) and

a downstream meter run (5D) are installed

Applicable fluid

- gasoline

- kerosene

- light oil

- heavy oil

- other

GENERAL SPECIFICATIONS

| Applicable fluids | Oil, heavy oil, other liquids (Homogeneous liquid through which an ultrasonic wave propagates) | ||

| Nominal size | 100, 150, 200, 250, 300mm | ||

| Number of lines measured | 4 | ||

| Flange standard | JIS 10, 20, 30K RF / JPI 150, 300 RF / ASME 150, 300 RF | ||

| Flow velocity measuring range | −10 to +10m/s | ||

| Accuracy | ±0.5%RD (Standard), ±0.15%RD (high accuracy calibration) | ||

| Temp. range | −20 to +120°C | ||

| Max. operating pressure | Depends on flange rating (Design pressure : 8MPa at 120°C) | ||

| Configuration | Explosionproof (TIIS, ATEX), IP66 | ||