This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

IMPULSE WELDER

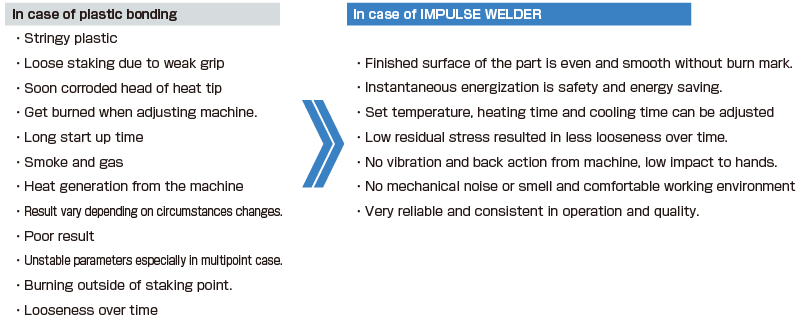

The IMPULSE WELDER is a heat staking system with instantaneous heating and cooling which is safe, stable, and energy-saving.

It is also environmentally friendly in terms of easy recycling of parts.

Maker:

Munekata Industrial Machinery Co,, Ltd.

Features

The mechanism of IMPULSE WELDER

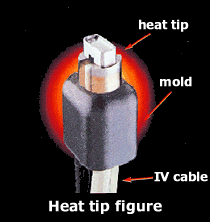

The impulse welder operates by applying an electrical current to the heat tip, causing it to heat up through Joule heating. This heated tip melts and forms the thermoplastic material. Subsequently, cool air is blown to solidify the plastic.

The impulse welder operates by applying an electrical current to the heat tip, causing it to heat up through Joule heating. This heated tip melts and forms the thermoplastic material. Subsequently, cool air is blown to solidify the plastic.

The welder is capable of staking multiple points simultaneously, handling up to 100 points in the same time as it would for a single point, though the exact time may vary depending on the size of the heat tip.

Example of use

The impulse welder continues to be utilized for various applications, consistently demonstrating strong performance and versatility. Its multi-purpose design meets a wide range of needs, ensuring reliable results across different use cases.

Compatible Welding Resins

■ABS ■PP ■PS ■PE ■PC ■POM ■PMMA

■PBT ■ABS/PC ■PPS ■PPA ■PET ■PA etc.

*Our extensive product lineup reflects our proven welding capabilities to date. We can also weld materials containing glass fibers, subject to consultation.

Handy Machine

In addition to the grip type, the slide unit (Munekata original mechanism) can be used to incorporate into hand presses, robots, and equipment.

■Timer control type: Achieve the stable heating that directly leads to improved welding quality

| Product | Features | Specifications |

|---|---|---|

| MIW71-1

|

Temperature Display: Displays the temperature of the welding tip with a thermocouple.

Advanced Functions: Includes error signal output, program selection, and air pressure detection (sensor required). Voltage Output: Outputs the tip temperature as a voltage signal. Audible Alert: Buzzer activation for detachment timing. *Options available

■Grip Type: Designed for handheld operations (thermocouple attachment not available). ■Slide Unit: Available in hand press and equipment integration types. |

Input voltage: AC 100V

Power consumption: 265W Air pressure: 0.4MPa~0.5MPa Welding time: 5 to 15 sec Welding tip size: Standard ø2 to ø7 (reference) Product dimensions: 304(W)×212(D)×130(H) Product weight: 6.5kg |

| MIW71-2

|

Temperature Display: Displays the temperature of the welding tip with a thermocouple.

Advanced Functions: Includes error signal output, program selection, and air pressure detection (sensor required). Voltage Output: Outputs the tip temperature as a voltage signal. Audible Alert: Buzzer activation for detachment timing

■Tip Block Type: Designed for precise and efficient operation. |

Input voltage: AC 200V

Power consumption: 364W Air pressure: 0.4MPa to 0.5MPa Welding time: 5 to 15 sec Welding tip size: Special heat tip Product dimensions: 400(W)×330(D)×160(H) Product weight: 12.5kg |

| MIW72-1

|

Dual-Point Welding Control: Supports control for welding at two points.

Temperature Display: Displays the temperature of the welding tip with a thermocouple. Advanced Functions: Includes error signal output, program selection, and air pressure detection (sensor required). Voltage Output: Outputs the tip temperature as a voltage signal. Audible Alert: Buzzer activation for detachment timing.

■Tip Block Type: Designed for precise and efficient dual-point welding operations. |

Input voltage: AC 100V

Power consumption: 455W Air pressure: 0.4 MPa to 0.5 MPa Welding time: 5 to 15 sec Welding tip size: Standard ø2 to ø7 Product dimensions: 400(W)×330(D)×160(H) Product weight: 14.0kg |

| MIW72-2

|

Dual-Point Welding Control: Supports control for welding at two points.

Temperature Display: Displays the temperature of the welding tip with a thermocouple. Advanced Functions: Includes error signal output, program selection, and air pressure detection (sensor required). Voltage Output: Outputs the tip temperature as a voltage signal. Audible Alert: Buzzer activation for detachment timing.

■Tip Block Type: Designed for precise and efficient dual-point welding operations. |

Input voltage: AC 200V

Power consumption: 707W Air pressure: 0.4MPa to 0.5MPa Welding time: 5 to 15 sec Welding tip size: Supports special heat tip Product dimensions: 400(W)×330(D)×160(H) Product weight: 18.5kg |

■Temperature control type: Secure stable quality with temperature setting and management functions

| Product | Features | Specifications |

|---|---|---|

MIW81-1/MIW81-2

|

Dual Control Methods: Select between temperature control and timer control modes.

Control Backup: Temperature control recording function allows operation in timer control mode if a thermocouple malfunction occurs. Advanced Functions: Includes error signal output, program selection, and air pressure detection (sensor required). Voltage Output: Outputs the tip temperature as a voltage signal. Audible Alert: Buzzer activation for detachment timing.

■Tip Block Type: Designed for precise and efficient dual-point welding operations. |

Input voltage: AC100V/200V

Power consumption: 270W~370W Air pressure: 0.4MPa~0.5MPa Welding time: 5 to 15 sec Welding tip size: Supports special heat tip. heat tip size ø2.5 to ø7 Product dimensions: 330(W)x280(D)x160(H) Product weight: 9kg/12kg |

■Multiple Points Machine

Munekata offers custom-made solutions tailored to your specific requirements. We can propose multi-point machines with various specifications to meet your needs. Please feel free to contact us for more information and to discuss your custom solution.

|

|

| Tabletop Model

Ideal for welding small products (workpieces) at one or a few points. This compact design is perfect for precision tasks in smaller work environments. |

Floor Model

Suitable for welding large products (workpieces) with multiple welding points. We offer a wide variety of types, including front-and-back sliding combinations and turntable models, to meet diverse welding needs. |

|

|

| Control Unit

Can be integrated into welding equipment for seamless operation and enhanced control. |

Video

Technical Data

Basic Welding Process

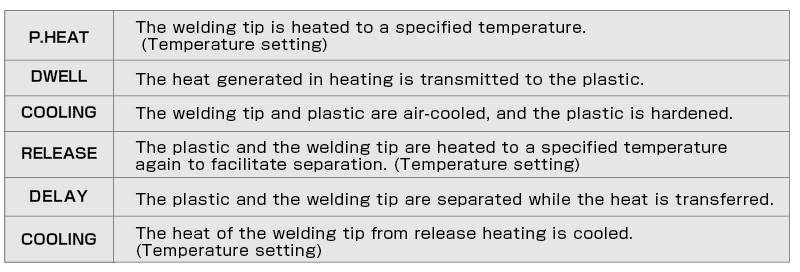

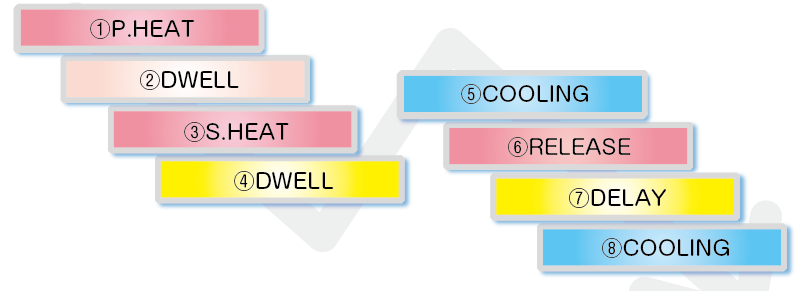

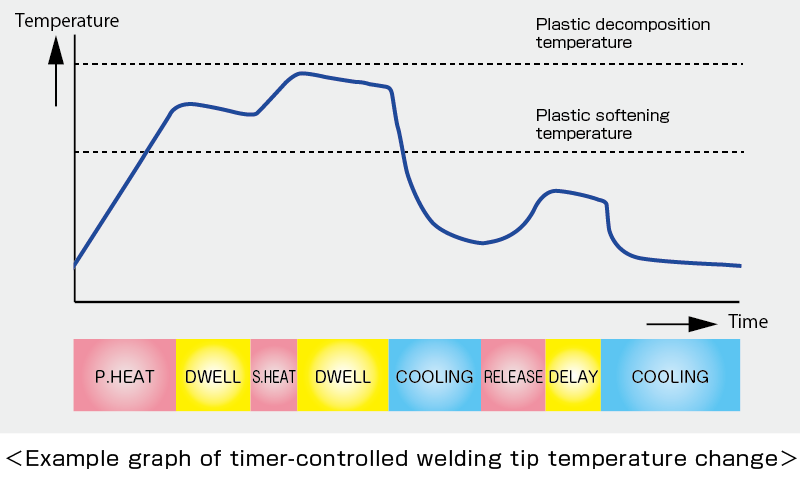

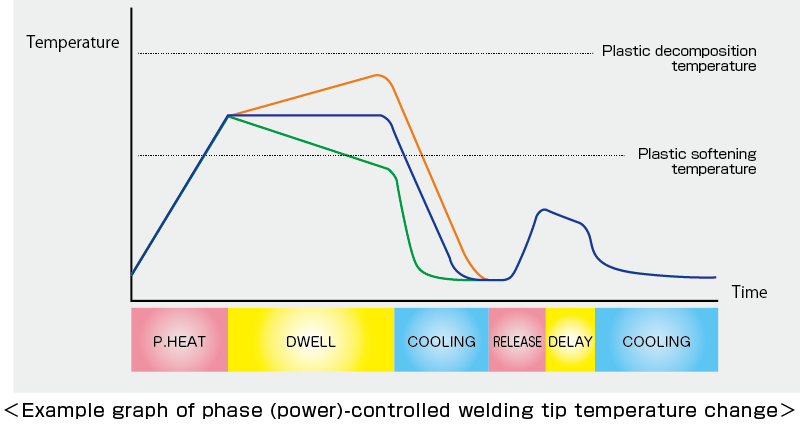

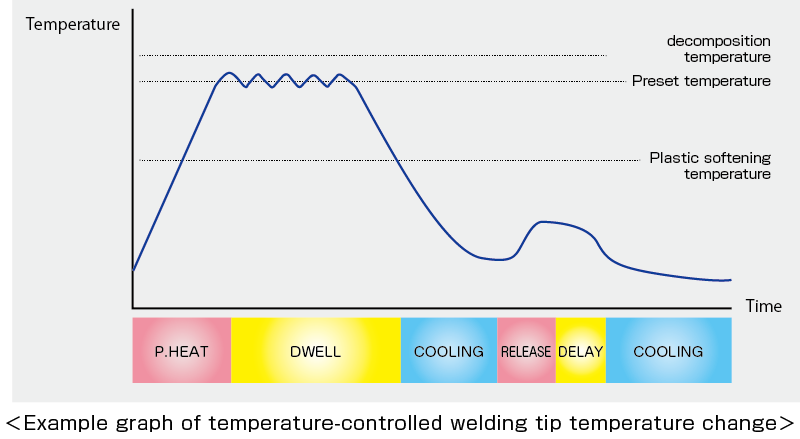

The Impulse Welder controls the welding conditions as follows. The roles of each step are described below.

1.Timer control method

2.Phase (power control) method

Heating and welding can both be accomplished through the heating process. Heating, welding, and cooling can each be input via a timer. By setting the phase control level (heating), the angle of temperature increase can be adjusted. Additionally, by setting the phase control level (welding), the welding time can be maintained at a stable temperature.

3.Temperature control method

Set the temperature for the heating, post-welding heating, and cooling end phases. This allows for stable heating and welding processes. Additionally, the system can adapt to fluctuations in power supply voltage (within specified limits).