Last updated: June 14, 2024

Key Takeaways

- What Strain Is: Understanding the basics of strain as the deformation of a material under force.

- How Strain Gages Work: The principle behind strain gages and how they measure strain through changes in electrical resistance.

- Choosing the Right Strain Gage: How to select strain gages and measuring instruments suitable for different purposes and environments.

- Types of Strain: The difference between static strain (slow changes) and dynamic strain (rapid changes), and their applications in various structures.

Understanding Strain: A Key Metric in Structural Integrity

Structures of various shapes and sizes, made from different materials, need to be monitored for strain. This includes transportation vehicles like automobiles, aircraft, railway cars, and ships, as well as civil engineering and building constructions such as dams, bridges, and skyscrapers. Measuring the stress within these structures is crucial for ensuring their strength and safety, especially under severe operating conditions.

Knowing the stress is vital for designing optimal structures that embody unique ideas, achieve lighter weight, or select suitable materials. It also ensures strength and safety. While computer-aided stress analysis techniques have advanced and are now commonly used in design, experimental stress measurements using strain gages remain the most reliable and practical method.

Principles of Strain Gages

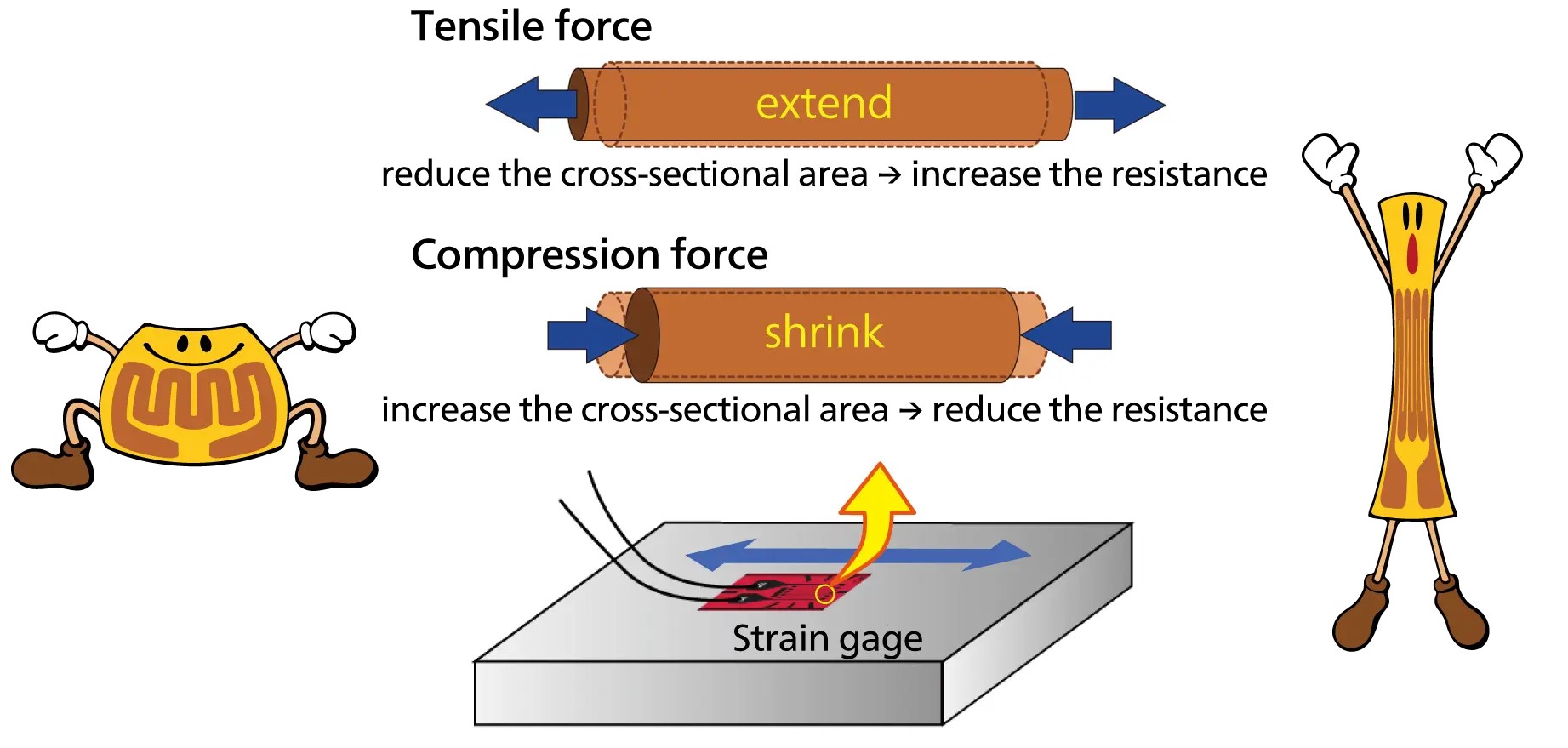

When a metal wire is subjected to a tensile force, it elongates, causing its cross-sectional area to decrease and its length to increase. This elongation results in a higher electrical resistance. Conversely, when the metal wire is compressed, its electrical resistance decreases. The relationship between the elongation or shrinkage of the metal and its electrical resistance is proportional and defined by a specific constant.

By bonding a metal wire (the strain gage) to a structure, the wire will elongate or shrink in accordance with the deformation of the structure. Measuring the change in electrical resistance of the bonded wire thus allows for the detection of the structure’s strain.

To ensure accurate measurements, the strain gage must be securely bonded to the target structure using a dedicated adhesive. This ensures that the strain gage deforms precisely with the structure.

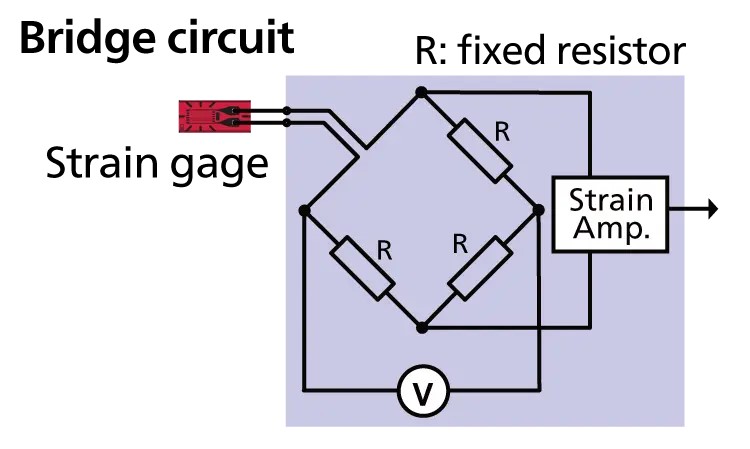

The resistance changes in strain gages are converted into voltage changes using a bridge circuit. Given that the voltage changes are typically very small (expressed in microvolts, μV), they must be amplified, usually by 5000 to 10000 times, for accurate detection and analysis.

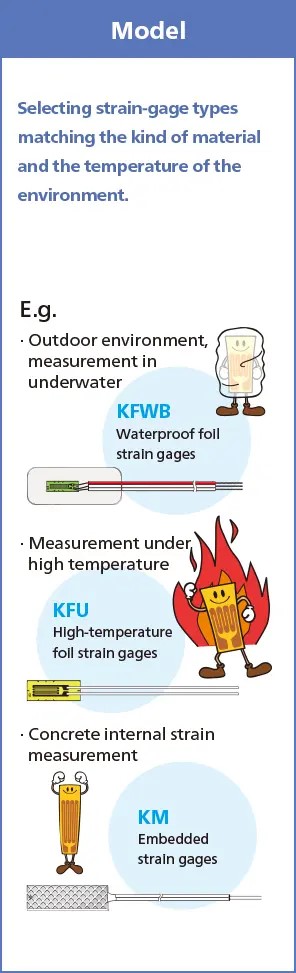

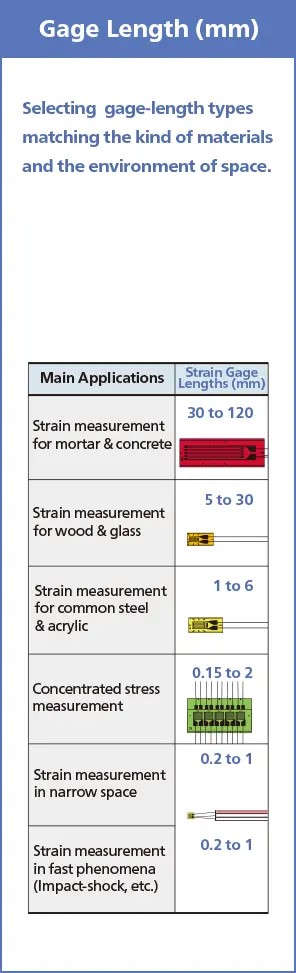

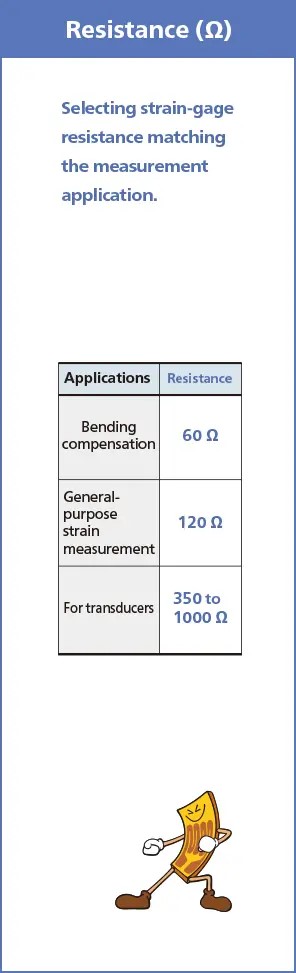

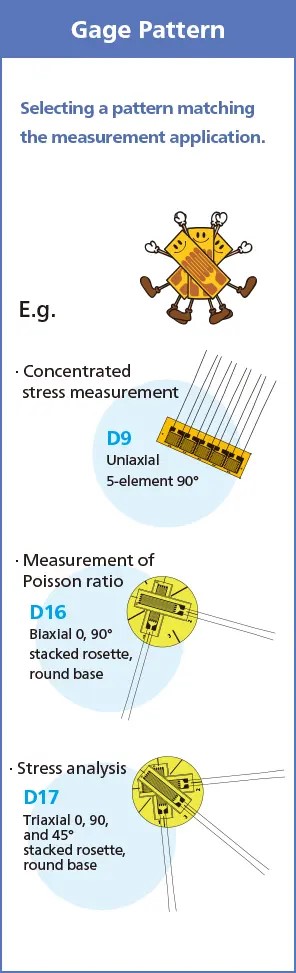

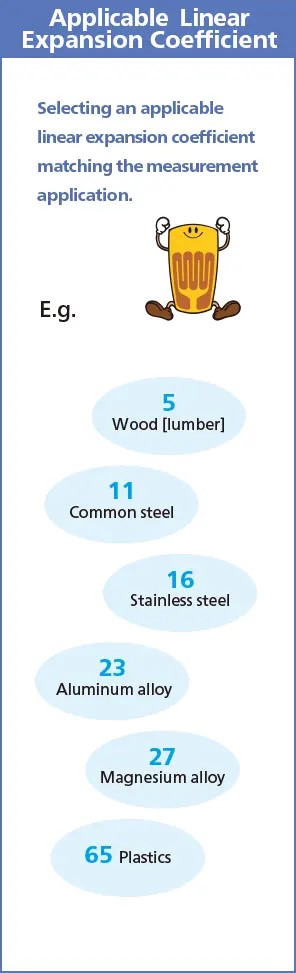

Selecting Strain Gages

Please click HERE for the detailed specifications of the strain gage

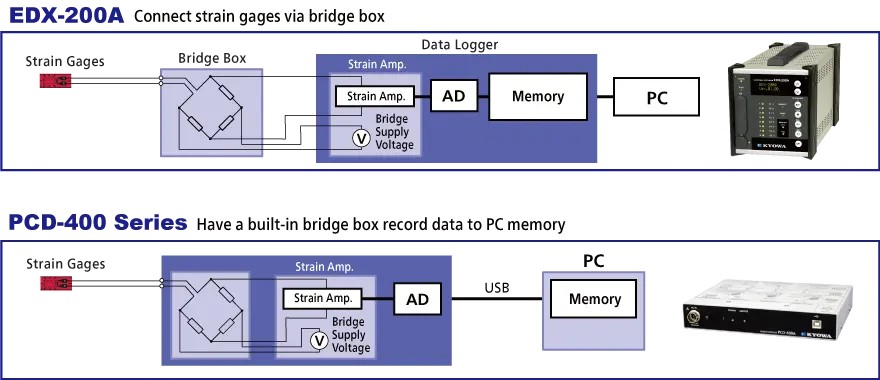

Selecting Measuring Instruments

Strain can be classified into two main categories based on the rate of change: static strain and dynamic strain.

Static Strain refers to stable strain or strain that changes very slowly over time. This type of strain is typically observed in structures under consistent and steady loads, such as buildings or bridges subjected to constant weight.

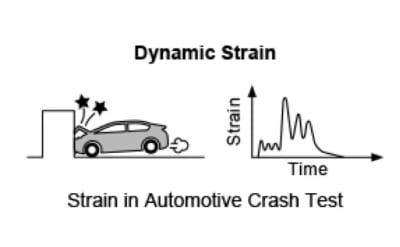

Dynamic Strain, on the other hand, refers to strain that changes rapidly. This is often seen in structures subjected to varying or cyclic loads, such as vehicles in motion or machinery with moving parts.

It is important to note that the distinction between static and dynamic strain is not always clear-cut. The transition between the two can be gradual, and the definitions can vary depending on the specific application or context.

Please click HERE for the detailed information