This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

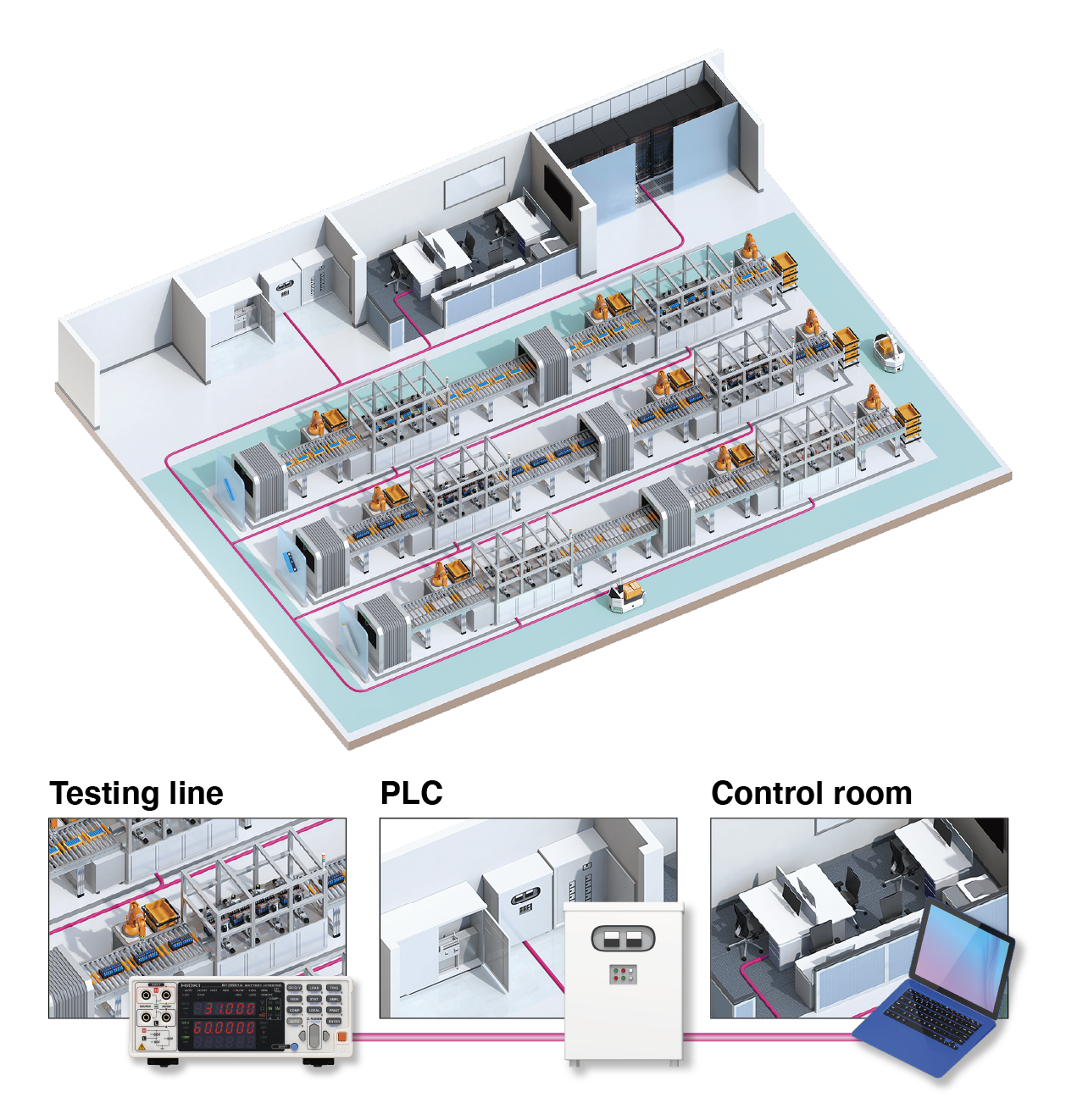

Fully Automated Production Line Testing of Large Packs for xEVs or Large Packs of up to 300 V

The HIOKI BT356xA series

These highly advanced battery testers are best suited for shipping and acceptance inspections of cells and battery packs. They simultaneously measure internal resistance and the battery’s open-circuit voltage (OCV).

Since the AC-IR measurement method is used, the measurement time is shortened. In addition, highly repeatable results are attained with this method. These testers have a highly accurate 3 mΩ range, allowing for a resistance measurement of battery tab welding and bus bars. All of this combines for the best choice in battery testers.

BATTERY HiTESTER

Model:

BT3563A

Maker:

HIOKI

Measuring battery performance and safety using internal resistance (AC-IR) and open-circuit voltage (OCV)

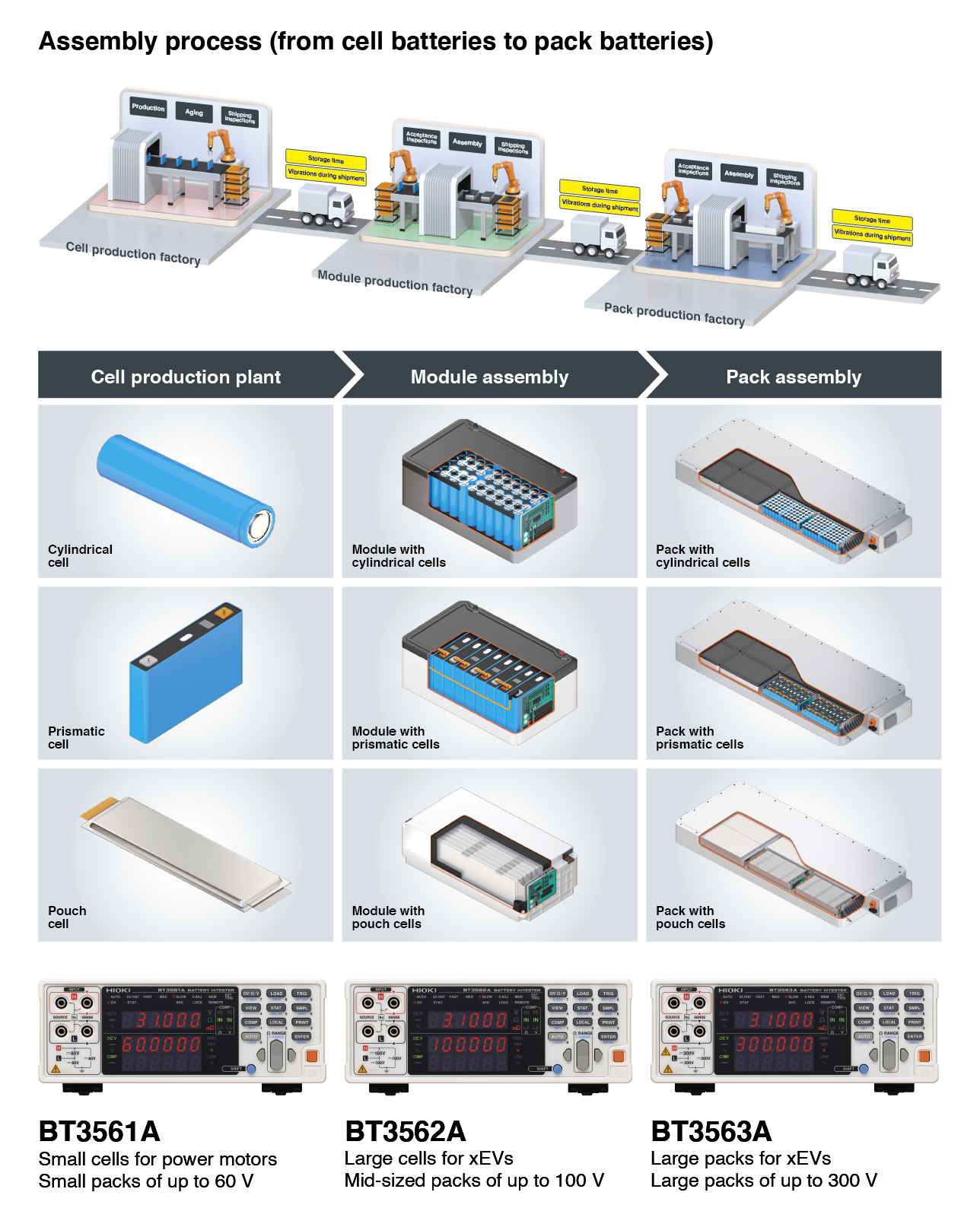

Inspect the quality of completed cells, modules, and packs on production lines. Measure internal resistance (AC-IR) and open-circuit voltage (OCV) to check battery quality. Cells produced at the cell production factory are shipped to the module production factory after undergoing a shipping inspection. Since factors such as vibrations during shipment and even the passage of time can cause defects, batteries undergo an acceptance inspection before being assembled into modules and packs.

BT3561A

Small cells for power motors, Small packs of up to 60 V

Voltage measurement ranges: 6 V/60 V

Resistance measurement ranges: 30 mΩ/300 mΩ/3 Ω/30 Ω/300 Ω/3 kΩ

BT3562A

Large cells for xEVs, Mid-sized packs of up to 100 V

Voltage measurement ranges: 6 V/60 V/100 V

Resistance measurement ranges: 3 mΩ/30 mΩ/300 mΩ/3 Ω/30 Ω/300 Ω/3 kΩ

BT3563A

Large packs for xEVs, Large packs of up to 300 V

Voltage measurement ranges: 6 V/60 V/300 V

Resistance measurement ranges: 3 mΩ/30 mΩ/300 mΩ/3 Ω/30 Ω/300 Ω/3 kΩ

Reducing test system development cost and management man-hours

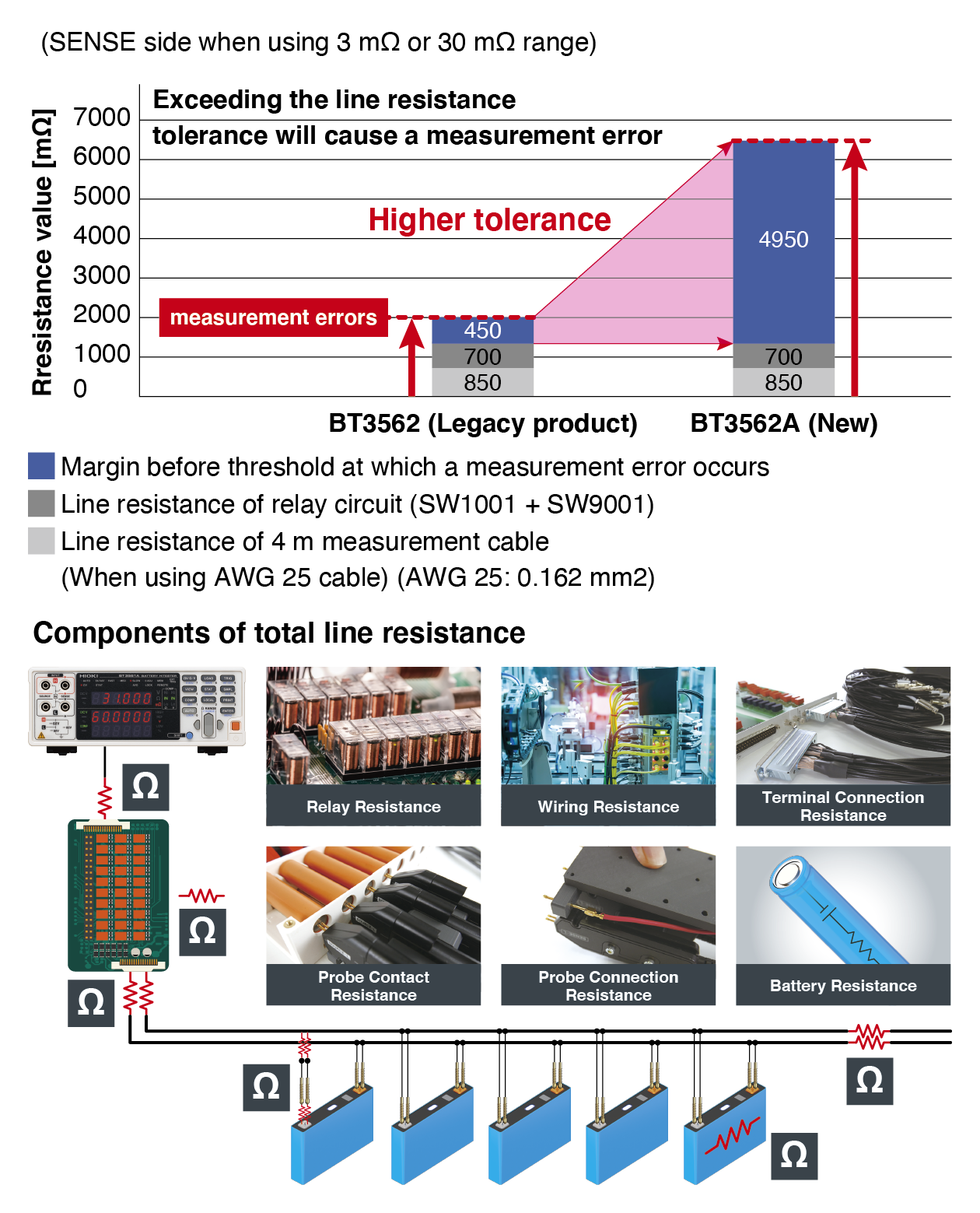

The new BT356xA has dramatically improved tolerances for line resistance compared to previous models. This improvement makes it easy to build test systems with large numbers of channels using relays. Additionally, a longer maintenance cycle for systems in use means fewer maintenance man-hours. Finally, its capability to handle thinner cables than with previous models* makes it easier to route cables.

*AWG 29 (0.064 mm2) wire equivalent to 2.2 Ω over

an 8 m round trip can be used with the 3 mΩ or 30 mΩ range.

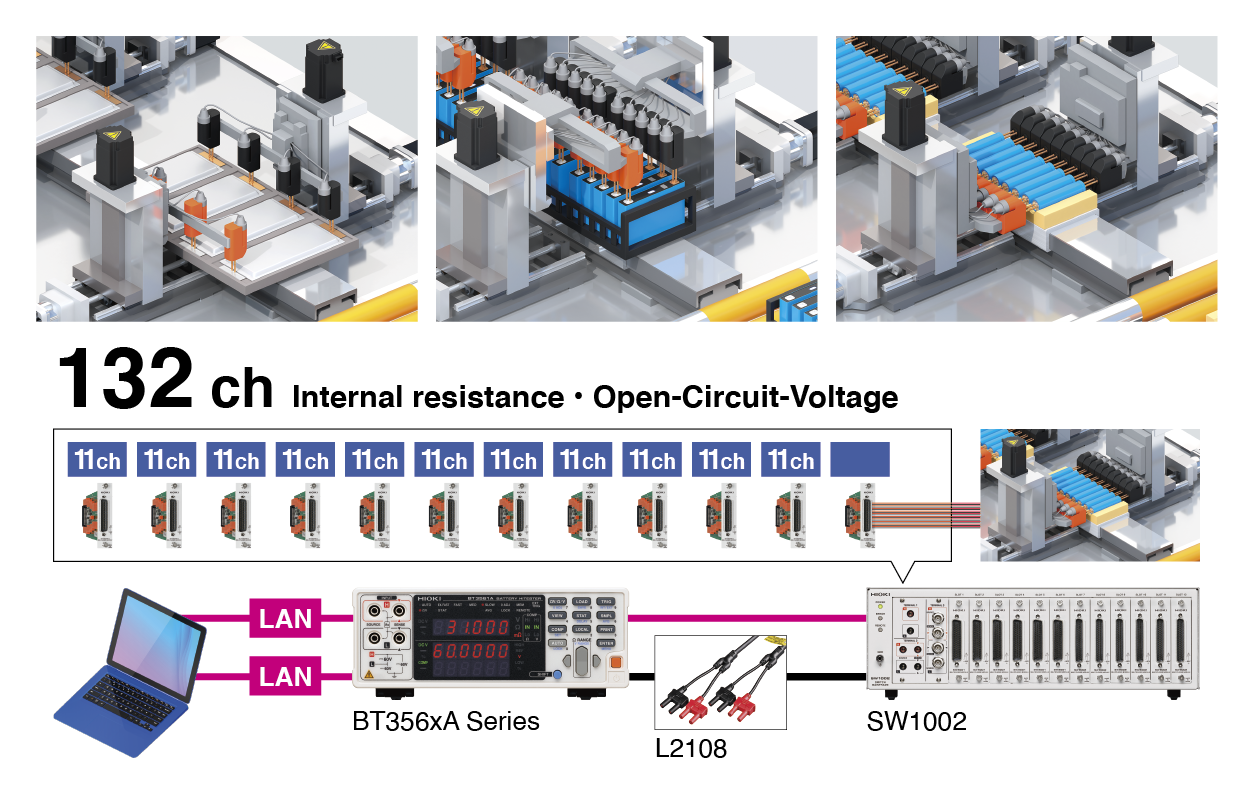

Improve Productivity by Increasing the Number of Inspection Channels

You can use the Switch Mainframe SW1001/SW1002 to increase the number of measurement channels. Additionally, you can perform scan measurement by controlling two instruments at once, for example a BT356xA series instrument and a DM7276, or a BT4560 and a DM7276.

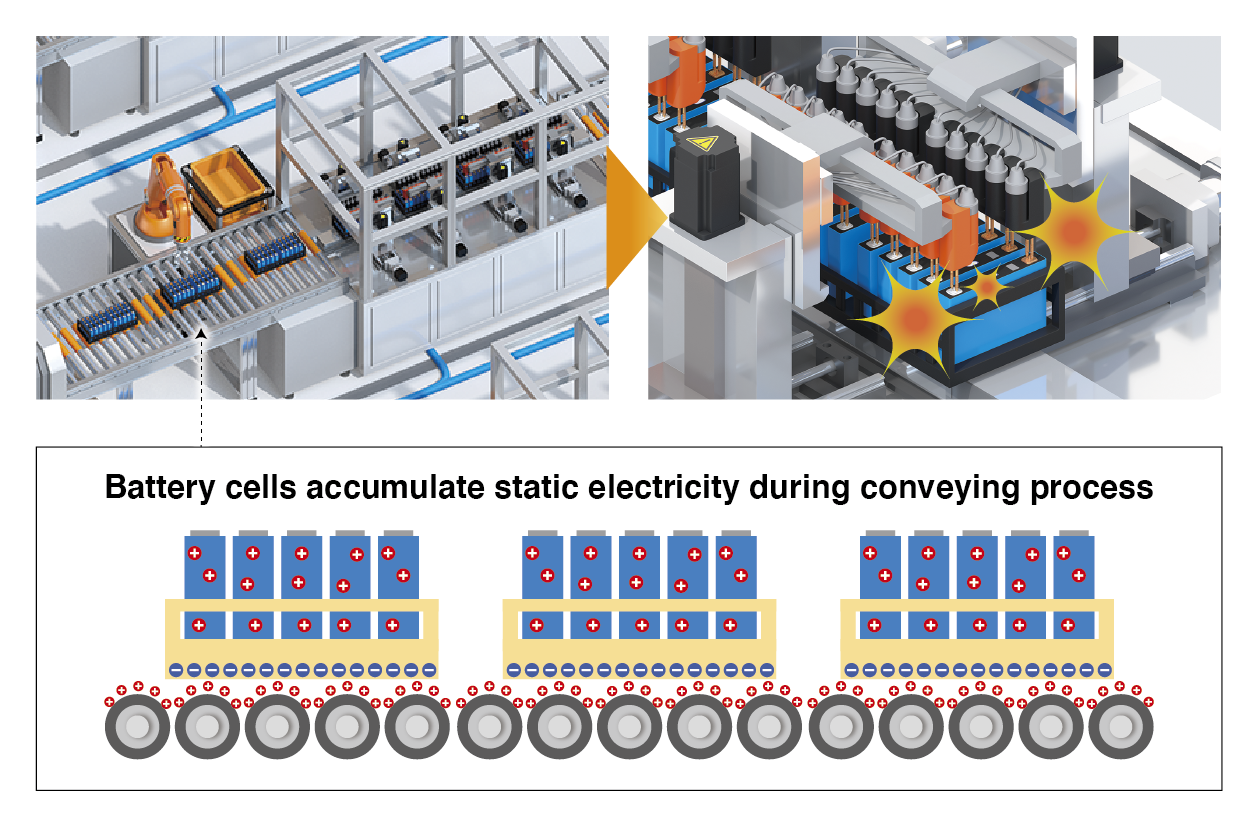

Preventing instrument malfunctions caused by static electricity

Batteries can become charged on production lines, for example, when being transported on a conveyor belt. When probes are placed in contact with such batteries, the resulting application of static electricity can then damage the instrument. The BT356xA series is designed to withstand contact with ±30 kV of static electricity*, preventing static-caused malfunctions and reducing testing line downtime.

* ±30 kV IEC 61000-4-2 contact discharge

LAN interface as standard

The BT356xA series is equipped with a LAN interface as standard equipment, making it easy for the instrument to interoperate with a PLC*-based control system. The ability to use readily accessible LAN cables helps lower costs during system development and maintenance. Furthermore, a design with strong noise and static electricity resistance helps avoid system problems.

*Programmable Logic Controller, a device that automatically controls one or more machines

Specification

| Resistance

measurement ranges |

3 mΩ(Max. display: 3.1000 mΩ, resolution: 0.1 μΩ, measurement current: 100 mA) 30 mΩ(Max. display: 31.000 mΩ, resolution: 1 μΩ, measurement current: 100 mA) 300 mΩ(Max. display: 310.00 mΩ, resolution: 10 μΩ, measurement current: 10 mA) 3 Ω(Max. display: 3.1000 Ω, resolution: 100 μΩ, measurement current: 1 mA) 30 Ω(Max. display: 31.000 Ω, resolution: 1 mΩ, measurement current: 100 μA) 300 Ω(Max. display: 310.00 Ω, resolution: 10 mΩ, measurement current: 10 μA) 3 kΩ(Max. display: 3.1000 kΩ, resolution: 100 mΩ, measurement current: 10 μA) Basic accuracy: ±0.5% rdg ±10 dgt(3 mΩ range), ±0.5% rdg ±5 dgt(30 mΩ range or more) |

| Voltage

measurement ranges |

6 V(Max. display: 6.00000 V, resolution: 10 μV) 60 V(Max. display: 60.0000 V, resolution: 100 μV) 300 V(Max. display: 300.000 V, resolution: 1 mV) Basic accuracy: ±0.01% rdg. ±3 dgt. |

| Response time | 10 ms |

| Sampling period | Ω or V (60 Hz): 4 ms (EX.FAST), 12 ms (FAST), 35 ms (MEDIUM), 150 ms (SLOW) ΩV (60 Hz): 8 ms (EX.FAST), 24 ms (FAST), 70 ms (MEDIUM), 253 ms (SLOW) Ω or V (50 Hz): 4 ms (EX.FAST), 12 ms (FAST), 42 ms (MEDIUM), 157 ms (SLOW) |

| Functions | Contact check, Zero adjustment (±1000 counts), Pulse measurement, Comparator (Hi/ IN/ Lo), Statistical calculations (Max. 30,000), Delay, Average, Panel saving/loading, Memory storage, LabVIEW® driver |

| Interfaces | LAN (TCP/IP, 10BASE-T/100BASE-TX) RS-232C (Max. 38.4 kbps, Available as printer I/F) EXT I/O (37-pin Handler interface) Analog output (DC 0 V to 3.1 V) |

| Power supply | 100 to 240 V AC, 50 Hz/60 Hz, 35 VA max. |

| Dimensions

and mass |

215 mm (8.46 in) W × 80 mm (3.15 in) H × 295 mm (11.61 in) D, 2.4 kg (84.7 oz) |

| Included

accessories |

Instruction manual ×1, Power cord ×1, Operating Precautions ×1 |