This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

The Best Way to Monitor and Visualize Cleanliness Level

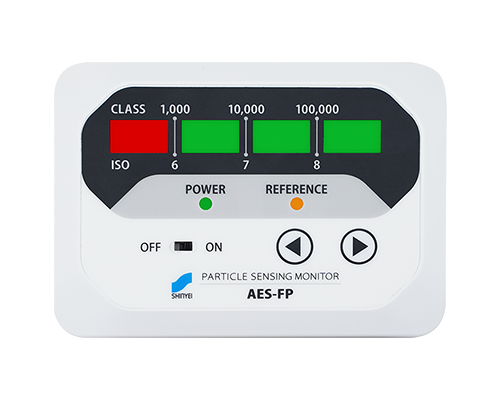

AES-FP series can detect particles over 0.3μm (or 0.5μm) in cleanroom, semiconductor/food manufacturing process, printing process, hospital facilities, and other environment requiring cleanliness monitoring at Class1,000 to 100,000.

LED display showing cleanliness level supports visualization of suspended particles and is useful for HACCP management. The sensor unit also can constantly detects particles over 0.3μm (or 0.5μm). The compact sensor design is suitable for incorporation into production equipment and installation in a narrow space.

Particle Sensing Monitor / Sensor Unit

Model:

AES-FP Series

Maker:

SHINYEI Technology Co.,LTD.

Key Features

- Capable to detect suspended particles at low cost.

If you need a monitoring function, use Particle Sensing Monitor. When incorporating into a production equipment and measuring at multiple locations, use Particle Sensor Unit independently.

-

Easy-to-check 4 step LED display for cleanliness level Class 1,000 to 100,000.

Simple operability and the display offers visualizing cleanliness level easily.

- Detect particles over

0.3μm (or 0.5μm) and over a few μm* (*reference value).

By detecting not only over 0.3μm (or 0.5μm) but a few μm(as reference) that is required for clean environment management, it helps to suppress the occurrence of quality defects due to particle adhesion in the manufacturing process of precision parts and work environment.

-

5 models available for suitable application and communication interface.

For Particle Sensing Monitor, 4 types of output/communication can be selected from alarm output, Ethernet, voltage output, and Wi-Fi. For Particle Sensor Unit, it can communicate with RS485.

-

Detachable sensor unit to maintain continuous measurement during calibration.

By using a spare sensor unit, continuous measurement can be done during the calibration. Sensor unit can be used independently.

-

Temperature and humidity sensor available as an option.

By connecting Temperature and Humidity sensor CHU-L (optional), the monitor can measure temperature and humidity constantly.

Application

For cleanliness management of semiconductor manufacturing, food factories and hospital environments.

- ProblemProduct quality and work efficiency are unstable.

- CountermeasureInstallation of Particle Sensing Monitor for each manufacturing area helps to monitor the frequency of particle generation constantly.

- AchievementProduct quality and work efficiency is improved.

For electrical rooms or server rooms of the data center.

- ProblemBreakdown of equipment in the electrical room (storage location for power supply system) due to insufficient indoor environment management occurs.

- CountermeasureParticle Sensing Monitor helps monitoring and visualizing the presence of particle generation in real-time.

- AchievementCleaning frequency can be controlled by visualizing particles inside.

For alarm trigger when the filter of clean booth or clean bench is damaged.

- ProblemFilter for the clean bench is broken during the work without noticing.

- CountermeasureParticle Sensing Monitor helps monitoring and visualizing the presence of particles in real-time.

- AchievementMonitoring particle generation in real-time helps to detect filter damage and reduce the work loss.

For improving manufacturing quality of semiconductors and precision parts.

- ProblemProduct defects and loss costs are increased due to foreign matter adhesion.

- CountermeasureParticle Sensing Monitor is installed for continuous monitoring of priority control points.

- AchievementFrequency of foreign matter generation is visualized and the number of defects is reduced after the countermeasure.

For status monitoring when the air conditioning system is off.

- ProblemCleanliness level is unknown when the air conditioner is stopped at night and restarted the next morning.

- CountermeasureTurning on Particle Sensing Monitor helps to know the cleanliness level when the air conditioning system is restarted.

- Achievement

Visualization of cleanliness tells you when the work should be started after the air conditioning system is ON.

Spesification

| Particle Sensing Monitor | Particle Sensor Unit | |||||

|---|---|---|---|---|---|---|

| Model #(0.3μm):AES-□□□: Model #(0.5μm):AES-□□□-5□: |

FPM-1 FPM-51 |

FPM-2 FPM-52 |

FPM-3 FPM-53 |

FPM-4 FPM-54 |

FPS FPS-5 |

|

| Optical Source | Laser Diode | |||||

| Measurement Range | Class1,000 to Class100,000(*1) | |||||

| Unit | pcs/m3(Default), pcs/cf, pcs/L(*2) | |||||

| Data Update Time | 1s | |||||

| Power | 12 to 24V(*3) | |||||

| Power Consumption (max) | +600mA | +200mA | ||||

| Operating Temperature | 0 to 40℃ | |||||

| Storage Temperature | -20 to 60℃ | |||||

| Operating Humidity | 30 to 80%rh | |||||

| Storage Humidity | Below 90%rh (No condensation) | |||||

| Output | LED Level Display | 〇 | 〇 | 〇 | 〇 | – |

| Reference LED | 〇 | 〇 | 〇 | 〇 | – | |

| Analog Voltage(1-5V) | – | – | 〇 | – | – | |

| Digital (Interface) | – | 〇 (Ethernet) |

– | 〇 (Ethernet) (Wi-Fi) |

〇 (RS485) |

|

| Alarm Output | 〇 | 〇 | 〇 | 〇 | – | |

| Temperature and Humidity Measurement(*4) |

– | 〇 | – | 〇 | – | |

| Weight | Approx. 210g | Approx. 65g | ||||

| Applicable Wire Size | AWG26 to 20 | |||||

- (*1)Class1,000 is reference information.

- (*2)Unit can be changed only for FPM-2/52/4/54. Unit for over a few μm is [pcs/min] as fixed.

- (*3)The dedicated AC adapter is supplied separately as an option.

- (*4)Temperature and humidity sensor (Model#: CHU-L151-11A-AES) is required as an option.

Specification for AES-FPM-□ & AES-FPS

| Particle Sensing Monitor | Particle Sensor Unit | ||||

|---|---|---|---|---|---|

| Model #(0.3μm):AES-□□□ | FPM-1 | FPM-2 | FPM-3 | FPM-4 | FPS |

| Detectable Particle Size | Over 0.3μm / Over a few μm(Reference) | ||||

| Output Average Time | 60s | ||||

Specification for AES-FPM-5□ & AES-FPS-5

| Particle Sensing Monitor | Particle Sensor Unit | ||||

|---|---|---|---|---|---|

| Model #(0.5μm):AES-□□□-5□ | FPM-51 | FPM-52 | FPM-53 | FPM-54 | FPS-5 |

| Detectable Particle Size | Over 0.5μm / Over a few μm(Reference) | ||||

| Output Average Time | 300s average value | ||||