This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

ITEMLIST

Products Infomation

Laser Scattering Particle Size Distribution Analyzer

HORIBA proudly introduces the newest breakthrough in particle size technology. This latest evolution in the LA series advances scientific knowledge for tomorrow's world through intuitive software, unique accessories, and high performance. The LA-960V2 continues HORIBA's proud tradition of leading the industry with innovative design.

Partica

Model:

LA-960V2

Maker:

HORIBA, Ltd.

Feature

HORIBA’s groundbreaking optical design perfects the static light scattering particle sizing technique.

- Advanced Detector Design

The number of detectors, angular range, and layout each contribute to overall system performance.

- Superior Instrument-to-Instrument Precision

The LA-960V2 is designed and built to provide the same experience regardless of manufacture date, operator skill, or geographic location. Achieve unmatched instrument agreement without the hassle of correlation.

- Automatic Laser Alignment in Seconds

Always make perfect measurements with computer-controlled laser alignment. The alignment process is finished in only a few seconds with HORIBA’s innovative approach.

- Guaranteed Accuracy and Precision

The LA-960V2 is a highly refined particle size analyzer capable of accurately measuring NIST-traceable size standards within 0.6% of specification. Fully compliant with ISO 13320 recommendations regarding the measurement of materials on the D10, D50, and D90.

State of the Art Sampling Systems

Wet Measurement

- Sample-to-sample analysis in less than 60 seconds

The HORIBA LA-960V2 wet circulation system is an easy, fast and very powerful dispersion system. The standard wet system offers a full package of a dispersant fill pump, liquid level sensor, circulation pump, 30 W in-line ultrasonic probe, and drain valve, which is all software-controlled for true one-button operation. This advanced design provides highly reproducible particle size results.

- Dry Measurement

- Automated, powerful dry-powder dispersion

The LA-960V2 PowderJet combines several unique and patented features to provide the most reproducible dry measurements. Use the Auto Measurement function to control vacuum, air pressure, powder flow, start/stop conditions, measurement duration, and data processing. Designed to handle every application including small sample amounts, friable powders, and highly agglomerated materials.

- Smart Scans – Trigger function

This function allows for very precious materials to be measured accurately. When the sample amount is limited or low flow ability, the Trigger functions perfectly to start and stop the measurement. - Self-Adjusting Powder Flow

Historically, the biggest challenge in dry powder measurement involved establishing an even powder flow. The LA-960V2 PowderJet has solved that challenge with a self-adjusting feedback loop to maintain a constant laser transmittance. This is a crucial factor in creating reliable, reproducible dry powder size measurements.

Specification

Laser scattering particle size distribution analyzer Model: LA-960V2

| Measurement

Principle |

Mie scattering and Fraunhofer diffraction |

|---|---|

| Measurement

range |

10 nm – 5000 μm |

| Measurement

Time |

Typical measurement takes 60 seconds from liquid filling, sampling and measurement to rinsing. |

| Measurement

Method |

Circulation measurement or fraction cell measurement (Fraction cell is optional) |

| Sample

Quantity |

Approximately 10 mg – 5 g (Depending on the particle size, distribution and density) |

| Dispersing

Volume |

Approximately 180 mL for standard pumping system, 5/10/15 mL for FractionCell accessory, Manual filling : 35 mL, Automatic filling : 40 mL for MiniFlow accessory. Approximately 1 L of LiterFlow option. |

| Available

carrier fluid |

Aqua* (A type), Organic solvent (S type) (*Ethanol can be used as a dispersing additive) |

| Communication | USB 2.0 |

| Light

Sources |

Red solid state 5 mW laser diode (650 nm), Blue solid state 3 mW LED (405 nm) |

| Dispersion

System |

In-line ultrasonic probe: 30 W, 20 kHz, adjustable levels Circulation pump: Fully automated fill and circulation pumps, 15 adjustable speeds, 4 selectable fill levels, 15 selectable circulation speeds (max: 10 L/min) |

| Operating

Conditions |

15〜35°C (59 to 95°F), relative humidity 85% or less (no condensation) |

| Power | AC 100-240V 50/60Hz, 300VA |

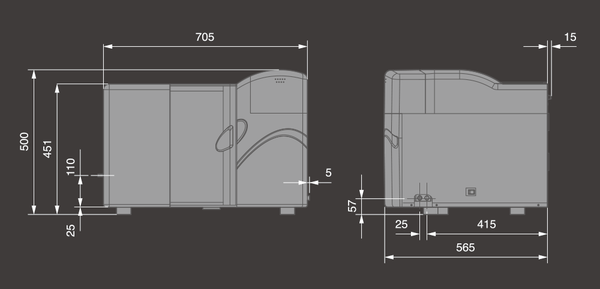

| Dimensions | 705 (W) × 565 (D) × 500 (H) mm |

| Mass | 54 kg |

| Computer

Requirements |

PC operation, Software compatible with Windows® 10 32-bit and 64-bit environments, *contact HORIBA for additional operating system compatibilities |

※Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

PowderJet Dry Feeder Accessory

| Dispersion

Method |

Compressed air dispersion using Venturi nozzle |

|---|---|

| Sample

Delivery |

Vibrating feeder |

| Sample

Disposal |

Vacuum-driven evacuation |

| Measurement

range |

100 nm – 5000 μm |

| Controls | Communication: Serial cable to LA-960V2 main unit Measurement: Vibrating feeder controlled automatically via feedback or manually by user, Vacuum AUTO/OFF, Compressed Air AUTO/OFF, Air pressure adjustable from 0 – 0.4 MPa in 40 steps |

| Measurement

Time |

Typical measurement takes 2 seconds or longer. |

| Operating

Conditions for PowderJet |

15〜35°C (59 to 95°F), relative humidity 85% or less (no condensation) |

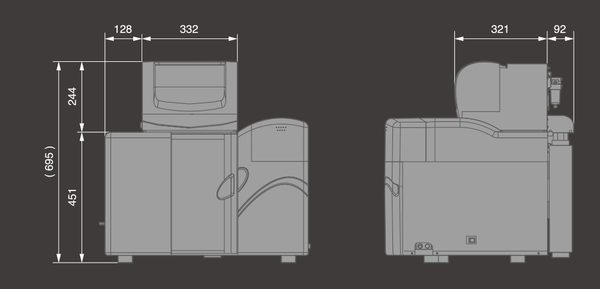

| Dimensions | 332 (W) × 321 (D) × 244 (H) mm (not including dimensions of projections and LA-960V2 measurement unit) |

| Power for

PowderJet Operation |

AC 100V, 120V, 230V, 50 or 60Hz, 1500VA (Including vacuum but LA-960V2 measurement unit) |

| Compressed Air

Supply Pressure |

Compressed air supply origin pressure: 0.4 – 0.8 MPa Compressed air controlling range: 0.01 – 0.4 MPa |

| Compressed Air

Connection |

Quick connector for resin tube with 6 mm outer diameter (Compressed air supply equipment must be provided separately) |

| Remarks | Vacuum is equipped as standard |

※When ordering the PowderJet, please specify the power requirements for the final destination.

※Above specifications and functionality are valid only when PowderJet is installed on the LA-960V2 main unit and controlled using the LA-960V2 software.

※Manufacturers and models indicated for vacuum, air compressor, computer, monitor, and/or printer are subject to change.

◎Air Compressor

Inlet pressure within 0.5 – 038 MPa, Tank capacity 26 L or larger, Flow rate 45 L/min or faster

LY-9610 Imaging Unit

| Measureable Range for image analysis | 9 – 1000 μm |

|---|---|

| Pixel Size | 0.73 μm |

| Speed | ≧ 4 fps |

| Functions | Histogram of equivalent circle diameter. Shape Parameters: Aspect ratio*, Circularity*, Length*, Width* Trend graph of equivalent circle diameter. Post Analysis of captured image (zoom-in/out, measuring size). |

*Optional Advanced software

Accessories

| Components | LA-960N2 | LA-960A2 | LA-960S2 | LA-960W2 | LA-960L2 | |

|---|---|---|---|---|---|---|

| Optics | Standard optical system | • | • | • | • | • |

| Aqua type Ethanol can be used as a dispersing additive. (0.01 – 3000 μm) | Standard circulation system | – | • | – | – | – |

| Pressurized fill adapter | – | – | – | • | – | |

| Liter flow | – | – | – | – | • | |

| Peristaltic pump system | – | – | – | • | – | |

| Solvent type(0.01 – 3000 μm) | Standard pump system | – | – | • | – | – |

| Accessories | Fraction cell holder | • | • | • | • | • |

| Mini-Flow with ultrasonic unit (0.01 – 1000 μm) | • | • | • | • | • | |

| Paste cell holder | • | • | • | • | • | |

| Dry unit (0.1 – 5000 μm) | • | • | • | • | • | |

| Auto sampler | – | • | • | • | • | |

| High Concentration Cell | • | • | • | • | • | |

External Dimensions (mm)